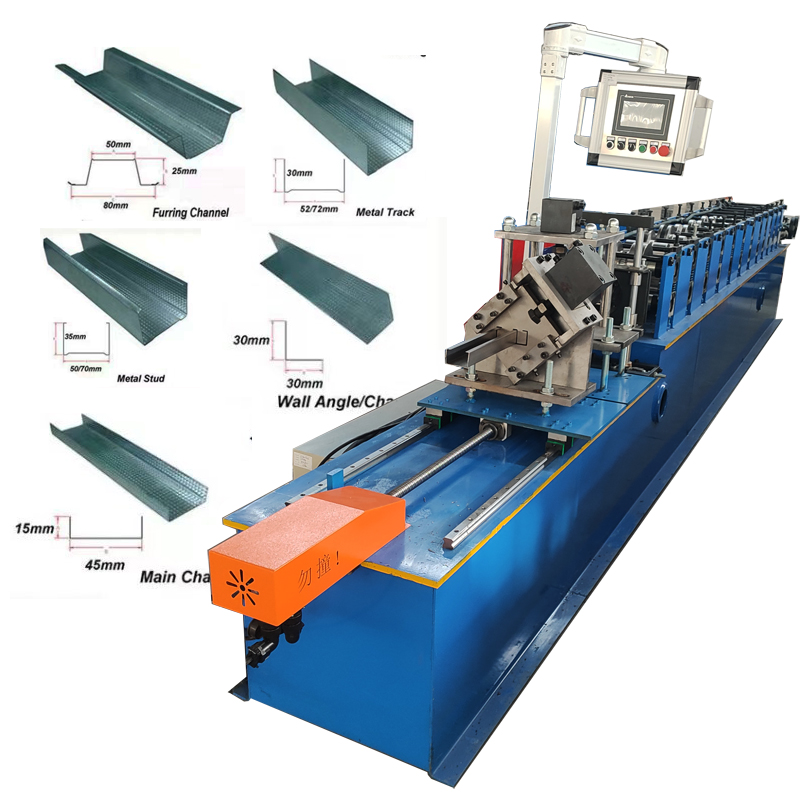

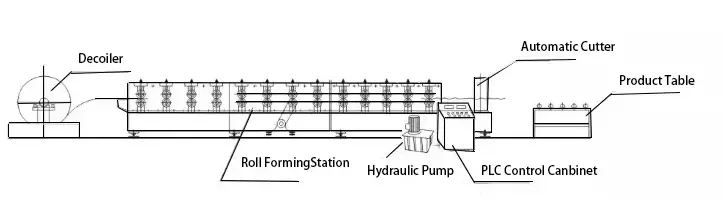

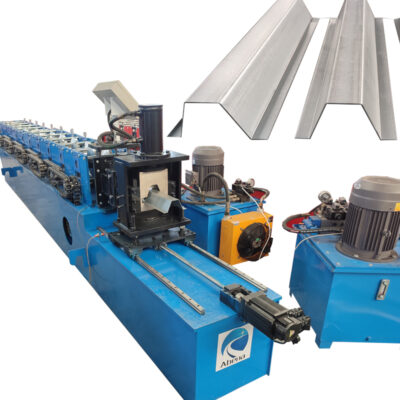

The components of the Popular Sale C U roll Forming Machine include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receving table.

The components of the Popular Sale C U roll Forming Machine include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receving table.

Equipment features: Suspended C U two profile making machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

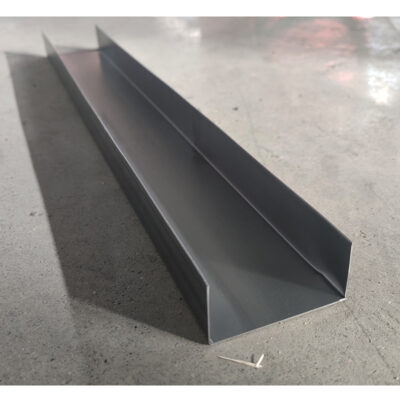

C Channle Forming Machine Product Description

Video Description

The complete production process is the basis for your choice of machine

Uncoiling —— Material Feeding —— Roll Forming —— Step Making —— Automatic Cutting —— Products Receiving

| Main parameters C channel roll forming machine | |

| thickness | 0.3-1.2mm |

| weight capacity | 3ton |

| Diameter of shaft | 55mm |

| Roller material | 45# with 0.05mm chrome |

| Frame | steel sheet welding |

| Frame thickness | 16mm |

| Cutting Material | Cr 12 |

| Working speed | 15-20m/minute |

| Main motor | 4kw |

| Voltage | 380v 50hz |

| Control systerm | PLC control system, inventer |

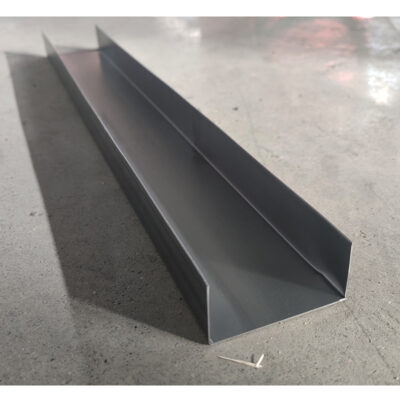

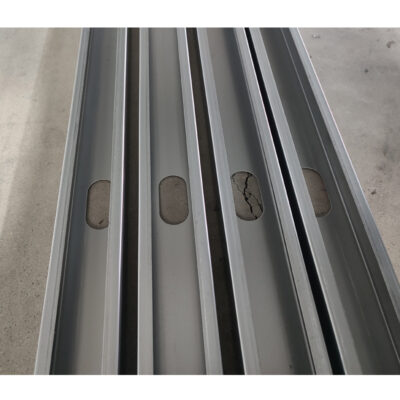

C Purlin Making Machine Details Images

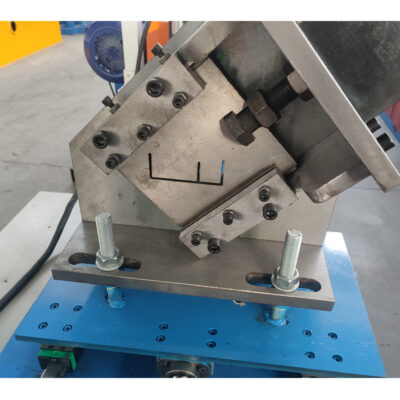

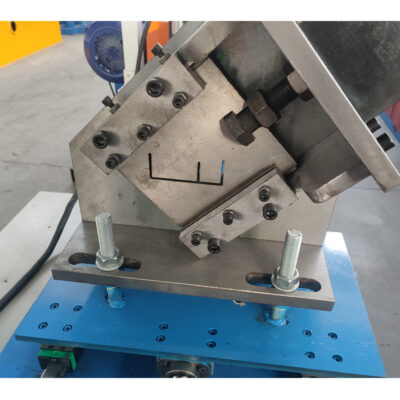

Hydraulic cutting

Controlled by oil pump

Automatic cutting as target products length Blade material: Cr12, quenching treatment

Roll forming body

Roller surfaces polish, hard plating dealing Polished surface and heat treatment towards molds can keep the molding plate surface smooth and not easy to be marked when it is being stamped

Decoiler

It is used to stand the steel coil and uncoil, keep them working stably.

Loading capacity: 3tons

computer control system

Button press and screen touch operate Target piece`s length is adjustable Work automatically The system operate easily

Our other products

u track roll forming machine angle wall light steel keel machine

omega light steel keel mchine

As a professional manufacturer,we can make double CU stud line light gauge keel stud track c channel steel roll forming machine by customer`s demand, with a profile drawing and thickness, we can design the machine quickly.Until now,we can do many kinds of roof panel machine,such as trapezoidal sheet making machine, corrugated sheet making machine, glazed tile making machine, Double Layer Roll Forming Machine and so on.