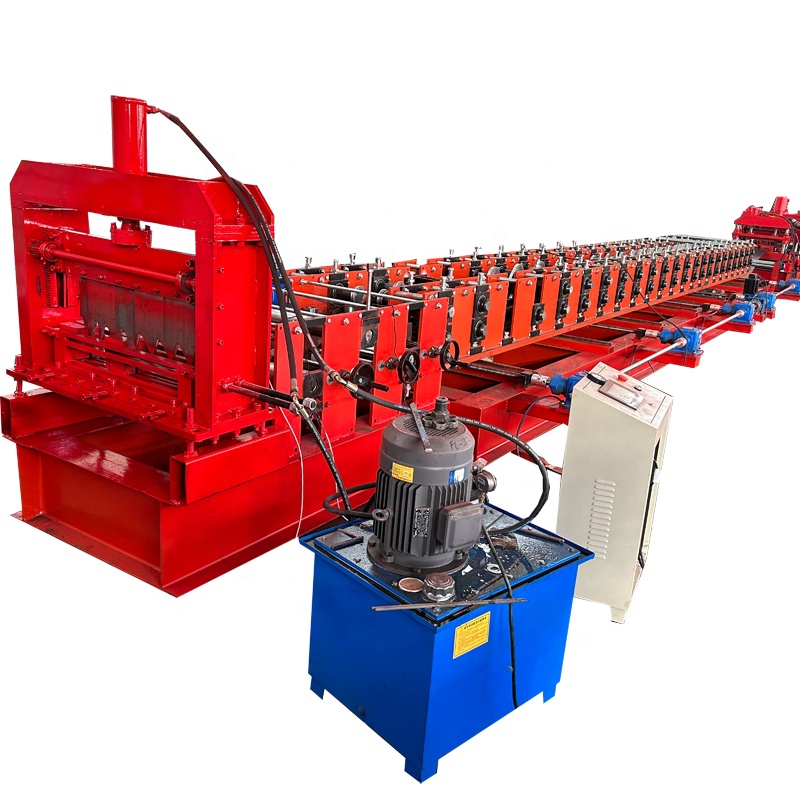

Cable Tray Making Machine Products Description

| cable tray machines Specification | |

| Raw material thickness | 2mm |

| Raw material | cold steel coil/ hot steel coil |

| Size of the web | 100-600mm |

| Control system | PLC Delta inverter |

| Cutting system | hydraulic cutting system |

| Roller station | 30 roller stations of main machine |

| Feeding machine | NC1250 servo feeding machine |

| Punching machine | JF21-200 punching machine |

| Decoiler | 7 tons decoiler |

| Dimension of machine | 25000*1500*1500mm |

| Weight of machine | 15 tons |

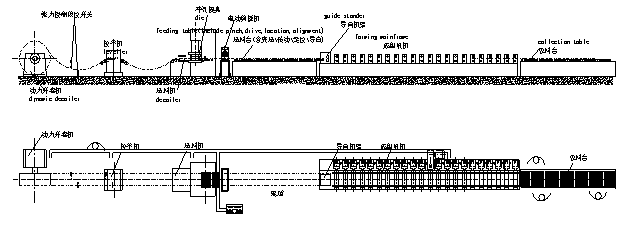

Main workflow of Trunk Type Cable Tray Making Machine:

Uncoiler —– Molding core —– Hydraulic System —– Automatic Control system —– Step Formed Mechanism —–Automatic Shearing Mechanism —– Products Receiving Tables

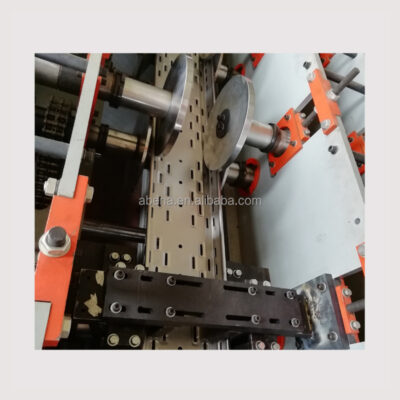

Cable Tray Roll Forming Machine Product display

Cable tray roll forming machine is capable of making different sizes of cable trays.

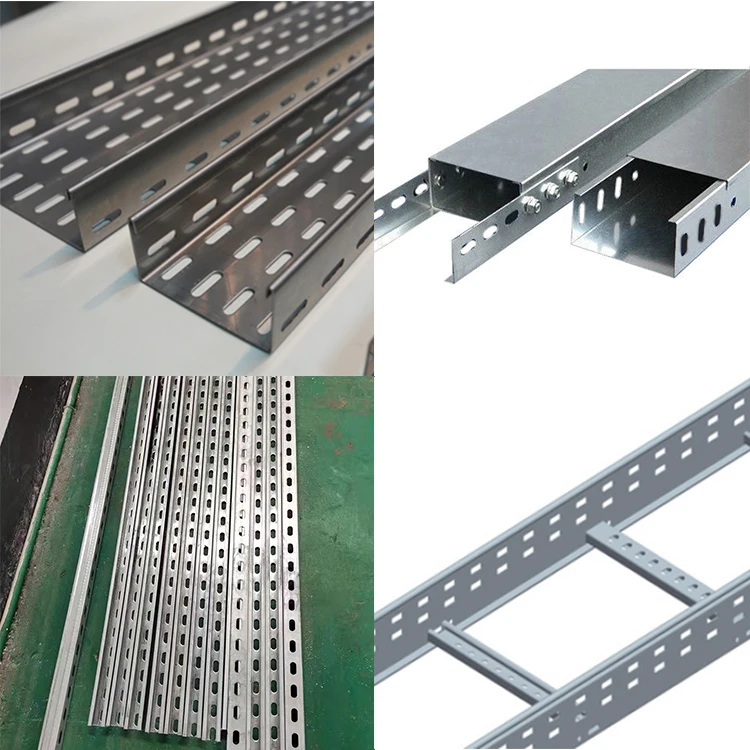

Perforated Type Cable Tray

This Cable Tray Roll Forming Machine can be adjusted easily to produce the Cable Trays Top and Bottom.The cable bridge is divided into trough type, tray type, ladder type, net format and other structures, which are composed of brackets, support arms and installation accessories. The bridge frame in the building can be erected independently or laid on various buildings (structures) and pipe gallery supports.