Double line roll forming machine Product Description

Main features of stud and track roll forming machine

1.The speed can reach 30-40 meters per minute

2.Enlarged hydraulic station to ensure high speed working

3.Easy operation, low maintenance cost

4.Beautiful appearance.

5.One machine for multi-profiles,size-changing by spacer

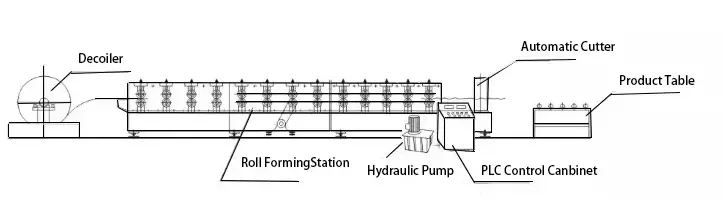

CU keel roll forming machine working flow

CU keel roll forming machine Specification

* Material: G.i Coil

* Material Thickness:0.4-1.0mm

* Cutting system: Hydraulic servo tracking fast speed cutting;

* Main Power: 5.5KW

* Hydraulic power: 2KW

* Servo motor power: 1.5KW

* Forming Station: about 10 steps ( adopt Italy Technology )

* Axis Diameter: ¢ 50 mm

* Material of rollers: Cr12.

* Forming Speed: 40-60m/min

* Forming Frame Structure: Guiding Column + Slide Blocks; This forming frame structure design is much high precision than wall plate welding structure

* PLC Brand: DELTA Brand

* Machine Diameter: about 5000mm(L)x800mm(W)x1700mm (H)

* Weight of machine: about 3 Ton

* Voltage: 380V, 3 Phase 50Hz ( or depend on customer’s requirement )

Double line making machine Details Images

1.High speed stud and track machine feeding guide

2.High speed stud and track machine rollers

3.High speed stud and track machine hydraulic cutting system

made by high quality long life mold steel Cr12Mov with heat treatment.

4.Electric control system

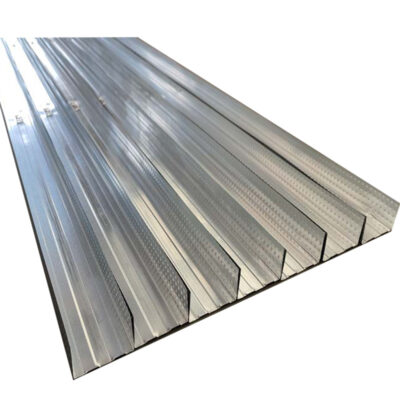

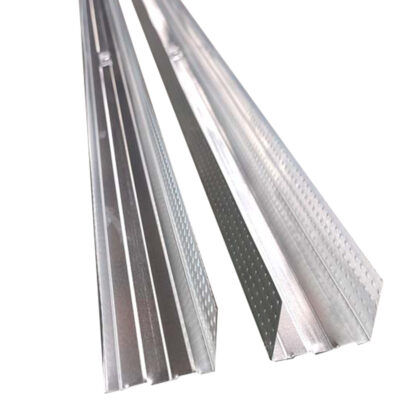

Finished product display

Various sizes can be customized