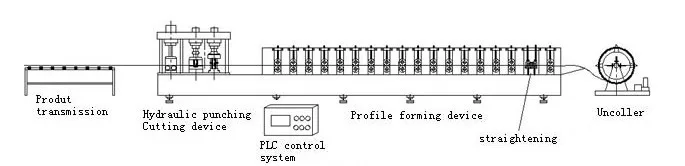

Corrugated Sheet Making Machine Product descriptions

Video Description

Corrugated Sheet Roll Forming Machine Product display

Uncoiling — Sheet guiding — Roll forming — Measure length — Pressure pattern — Cutting — Panels to product stand

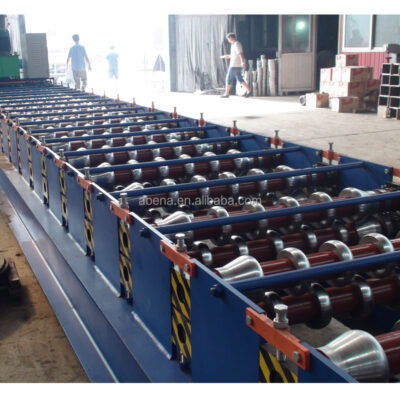

Corrugated machine pictures

This machine can customize the tile length according to the requirements there is the construction of the computer controller to set up multiple sets of different data easy operate, The equipment automatically set in accordance with the computer data to produce different lengths of finished products.

| Building material steel roofing sheet roll forming machine machinery | |

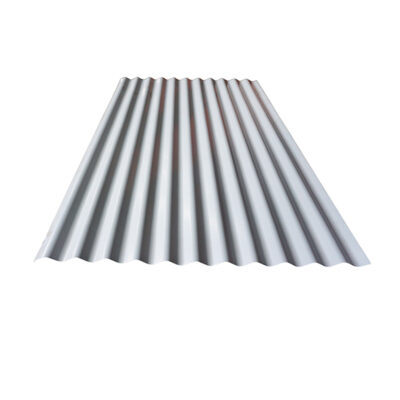

| Suitable raw material | PPGI/PPGL/GI/GL Steel Coils |

| Thickness of coil sheet | 0.3-0.8mm |

| Feeding Coil width | 1200mm |

| Effective width | 935mm |

| Under frame | 400H-beam |

| Diameter of Soild shaft | 70mm, high grade 45# steel, finish turning, cylindrical grinding, with keyway |

| Roller | High grade 45# steel, processed by CNC lathe, Quenched and tempered treatment,

hard chrome coated 0.05-0.07mm |

| Thickness of middle plate |

16mm |

| Forming stations | 23 |

| Power of main motor | 5.5kw with Cycloidal reducer |

| Forming speed | About 15-20m/min |

| Hydraulic cutting | Controlled by PLC |

|

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working Feature : Ensure stability , precision and lifetime. |

|

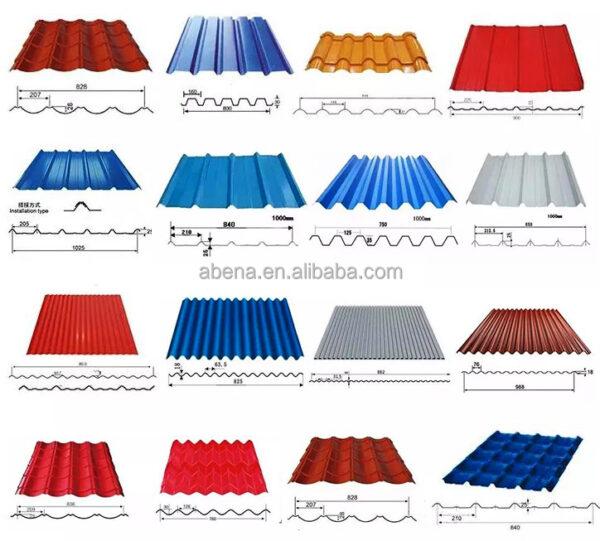

Finished product

These styles can be customized, you can contact us with the drawings you need.

Our company has always been adhering to the business philosophy of quality first and reputation first. Our company has been producing and operating various cold bending forming equipment for more than ten years. Our company has the most advanced technical team and rich production experience, and can produce machines according to your needs.