Omega Channel Roll Forming Machine Product Description

Video Description

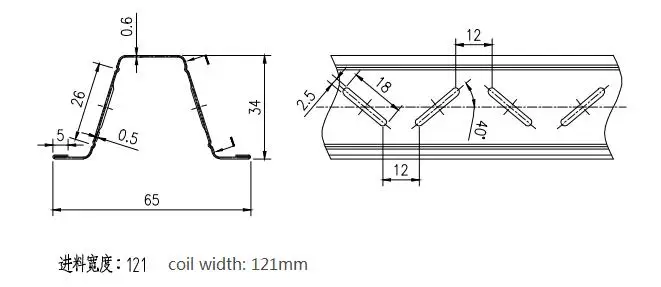

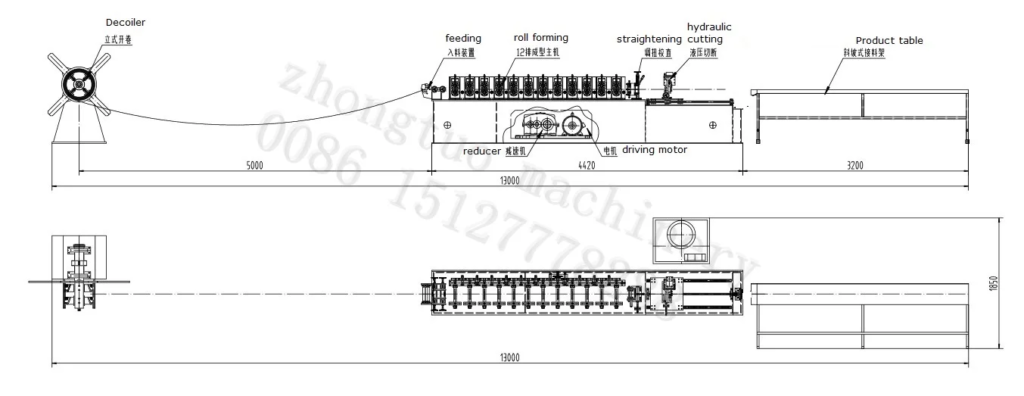

ZTRFM Ceiling System Omega furring channel cold roll forming machine light steel framing machine is used to produce the furring channel, the ceiling batten channel, the roofing batten channel for housees. The machine can work at the speed of 25 meters per minute, with servo motor tracking cutting. Machine body is pillar structural, with safety protection cover. There are two encoder to measure the length of the cutting productus, PLC is world famous PLC system. Whole ceiling batten, roofing batten machine is including below parts: 2 tons manual decoiler, leveling system, the main roll forming machine and tracking cutting system, and 2 sets output receiving table.

| Ceiling System Omega furring channel cold roll forming machine light steel framing machine | |

|

Formed Material

|

galvanized steel

|

|

Thickness

|

0.3-0.8mm

|

|

Material hardness

|

550MPA–350MPA

|

|

Power

|

as customer requirements

|

|

Formed width

|

100mm

|

|

Forming speed

|

40m/min

|

Omega Channel Cold Forming Machine Product display

Manual decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

1. Loading capacity: 1.5T

2. Uncoiling width: 300mm

3. Inner diameter: 450-550mm

2. Uncoiling width: 300mm

3. Inner diameter: 450-550mm

Feeding Part

This part will level coil to make sure it is neat clean and straight. Meanwhile the roller will punch dots at both side of the C channel.

Roll forming machine

1. Voltage: 380V/50HZ 3Phase (as customer’s request)

2. Roller fixer: Guide column

3. Frame: middle plate welded

4. Frame thickness: 25mm

5. Drive mode: gear

6. Material of rollers: GCr12MoV

7. Material of shafts: 45# steel with tempering

8. Diameter of shafts: φ40mm

9. Number of rollers: 10rollers

2. Roller fixer: Guide column

3. Frame: middle plate welded

4. Frame thickness: 25mm

5. Drive mode: gear

6. Material of rollers: GCr12MoV

7. Material of shafts: 45# steel with tempering

8. Diameter of shafts: φ40mm

9. Number of rollers: 10rollers

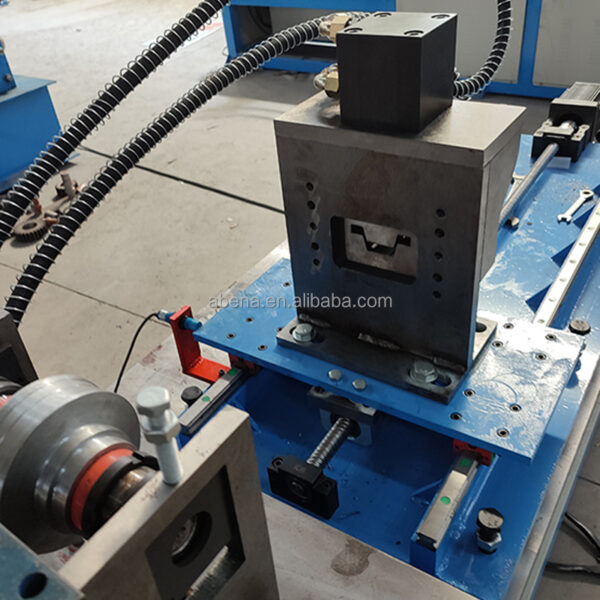

Shearing machine

Together with punching words, cutting will be done together.

1. Material of blades: Gcr12 quenched

2. Power supply: hydraulic power

3. Frame: Pillar style with rack & pinion system

4. Stroke switch: non-contact photoelectric switch

2. Power supply: hydraulic power

3. Frame: Pillar style with rack & pinion system

4. Stroke switch: non-contact photoelectric switch

Electric Control System

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta.

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and

safety.

Finished product

More for you choose