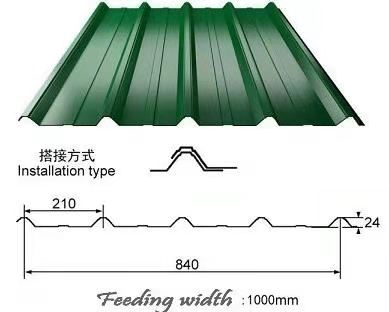

Trapezoidal roll forming machine Product Description

Video Description

Trapezoidal making machine Product display

Main roll forming

Thick tie rod and suit roll forming roller

Diameter: 80 mm

Power for the roll forming :5.5 kw

Hydraulic cutting device

Material of blade Gr12mov heat treatment60-62HRCIt is controlled by gear wheel oilpumpAfter filling the hydraulic oil into the hydraulicoil tank, the pumps drive the cutter machine tobegin the cutting job.The system includes: a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetismvalves.

Power of the oil pump: 4 kw Hydraulic oil :46#

PLC control system

The whole line is controlled by PLC and touch screen,The PLC system is with high speed communication module,it is easy for operation The control system is also with warning function to control the whole line work well

Feeding Device

new type feeding device,can make the sheet feeding smoothly and accurately.with pre-cutter ,can cut the steel sheet anytime you finished the production .high efficiency

Finished product photos

You can contact us with the drawings of the patterns you need. All patterns can be customized.

IBR roof panel roll forming machine Product Description

|

Feeding material

|

PPGl/aluminum/glgl |

| Thickness of the plate | 0.3–0.8mm |

| Diameter of the axle | 80mm |

| Rolling stages |

14 stages

|

| Productivity |

8 16m/min

|

| Total power | 5.5kw machine motor + 4kw pump station motor |

| Voltage | 220V 60Hz 3phase or as requirement |

| Cutting blade | Cr12 with heat treatment |

| Cutting system | Hydraulic cuting system afer forming |

| Control cabinet | PLC and frequency changer in it |

Our roofing sheet machine is customized, we will design and produce the machine as your personal requirements. Different country have different profiles, if you want this machine please just give me your profile.