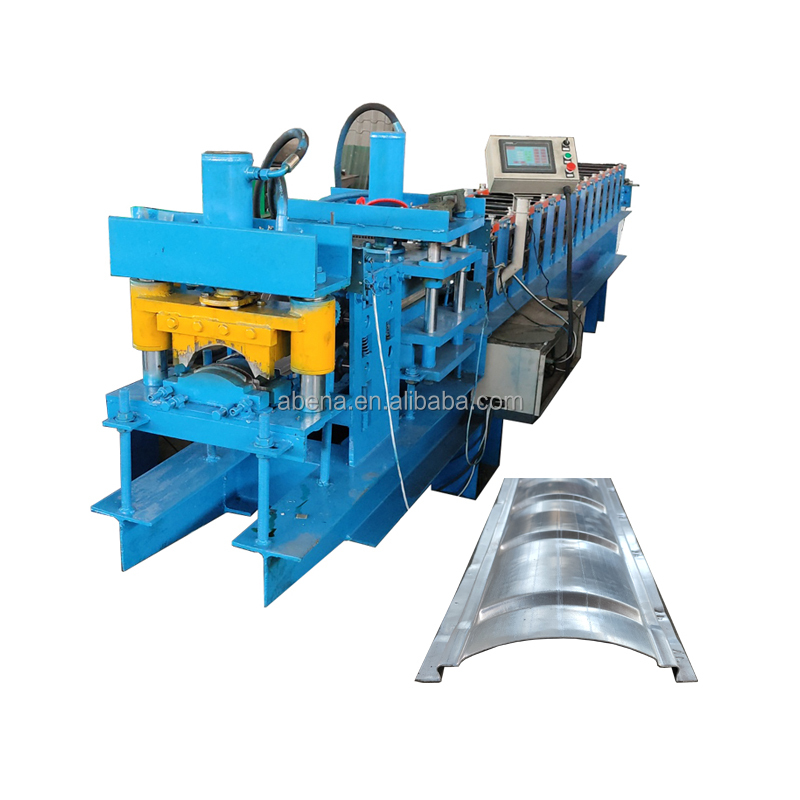

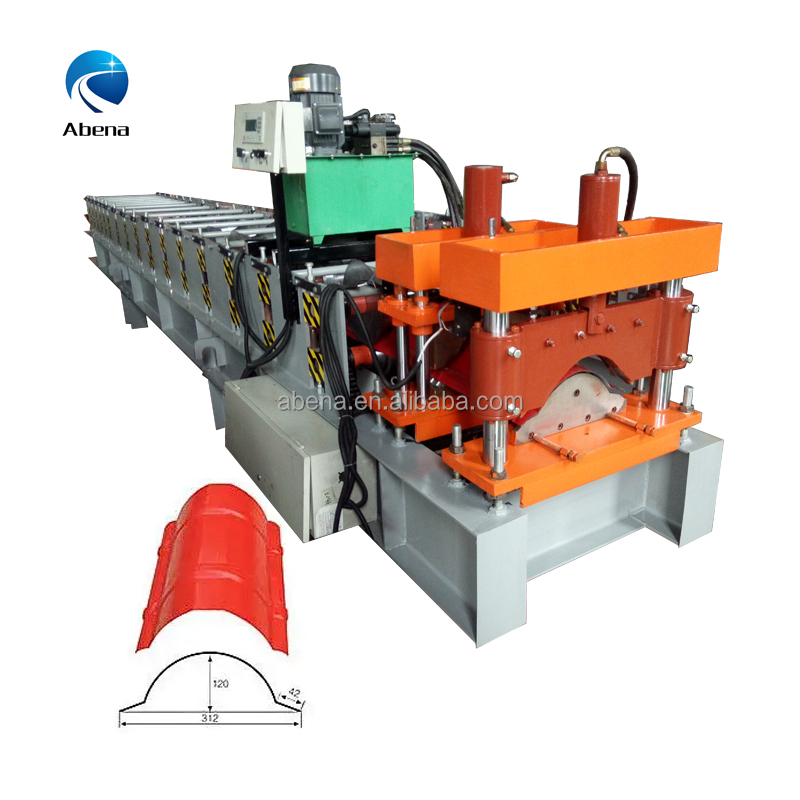

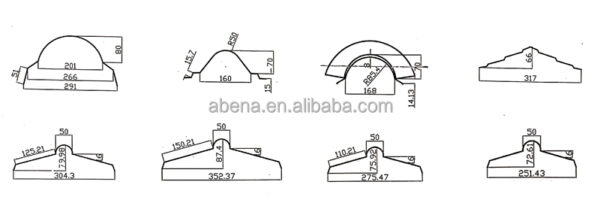

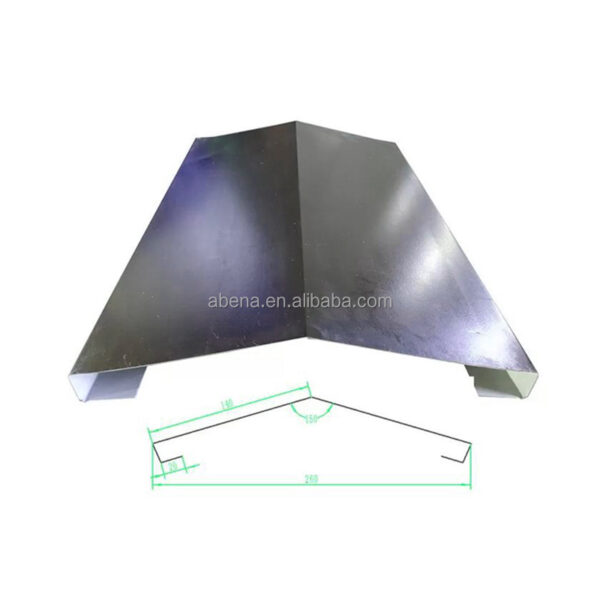

Ridge tiles can be understood as tiles with the same part that can drain water on both sides. To be precise, ridge tiles are channel tiles that cover the ridge and overlap with the tiles on the sloped roofs on both sides of the ridge. Randro ridge tiles can usually be made into herringbone, saddle, or arc shapes, and are used with clay tiles, glazed tiles, plastic tiles, asbestos cement tiles and other types of roofs.

Video description

| Main parameter Ridge cap roll forming machine | |

| thickness | 0.3-0.8mm |

| operate | manual |

| weight capacity | 5ton |

| roller station | 12 |

| Diameter of shaft | 70mm |

| Roller material | 45# with 0.05mm chrome |

| Frame thickness | 18mm |

| Cutting Material | Cr 12 |

| Working speed | 15-20m/minute |

| Main motor | 5.5kw |

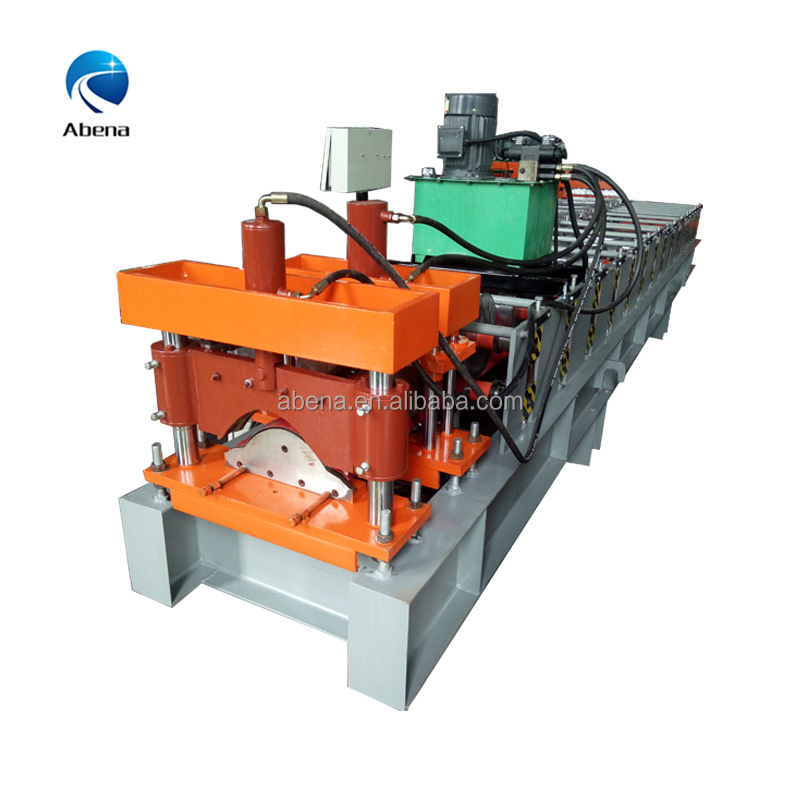

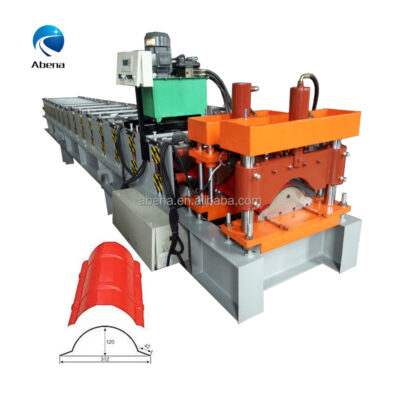

Roof Ridge Cap Machine Product details

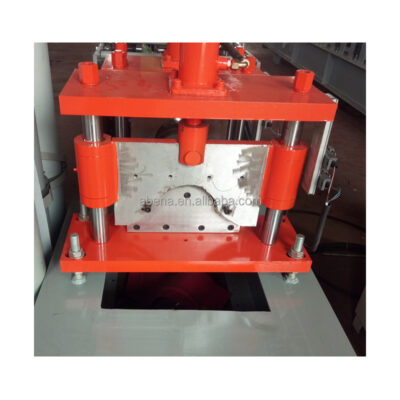

Hydraulic cutting

Controlled by oil pump

Automatic cutting as target products length Blade material: Cr12, quenching treatment

Roll forming body

Roller surfaces polish, hard plating dealing Polished surface and heat treatment towards molds can keep the molding plate surface smooth and not easy to be marked when it is being stamped

computer control system

Button press and screen touch operate Target piece`s length is adjustable Work automatically The system operate easily

Pump station

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter work

Hydraulic oil: 46#

Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa

Hydraulic oil: 46#

Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa

The components of the roof ridge cap roll forming machine include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receving table.

Equipment features: roof ridge cap roll forming machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Equipment features: roof ridge cap roll forming machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.