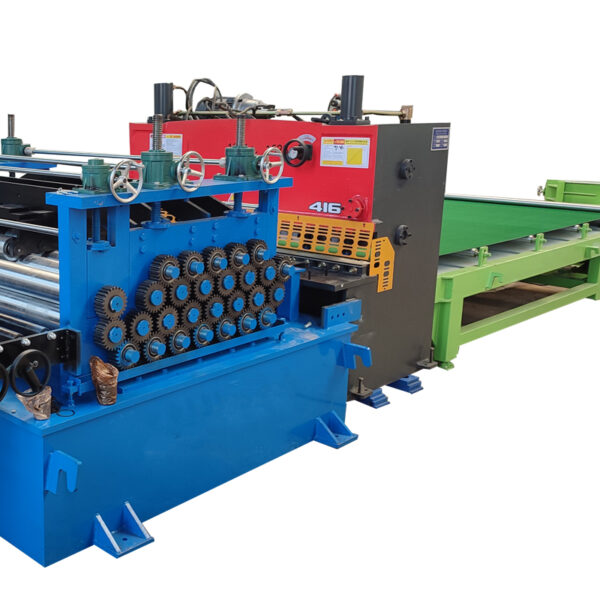

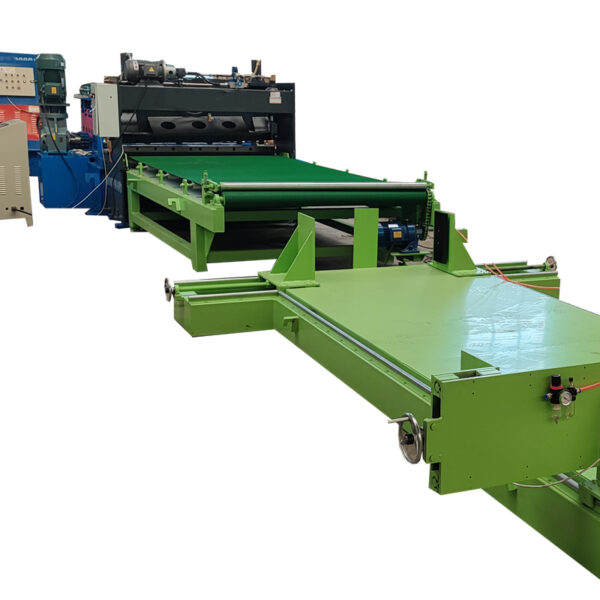

Automatic cut-to-length production line is high-speed and precise with workstations for uncoiling, straightening, measuring, cross-cutting to length and stacking. The machine consists of coil car, assisting support, decoiler, peeler device, leveler, coil guide, encoder scale, shearing machine, conveying table, stacker, output trolley, hydraulic system and so on. The whole line is controlled by PLC with computer display.This line is highly automatic with good straightening effect, précising cutting, efficient production, reliable performance, easy operation and maintenance.

Stainless Steel Cut To Length Product Description

Video Description of Cut to Length Line

Cut to length machine specification

|

Specification |

Unit | mm | |

| 1 |

Shearing thickness |

0.5-4 | mm |

| 2 | Shearing width | 600-1600 | mm |

| 3 | Plate tensile strength | 450 | n/mm2 |

| 4 | Shearing angle | 2.5 | degree |

| 5 | Strokes | 10 | n/min |

| 6 | Throat depth | 100 | mm |

| 7 | Length of blade | 1300*3 | mm |

| 8 | Blade material | 6CrW2Si | CrW2Si |

| 9 | Height of working table | 800 | mm |

| 10 | Back gauge range | 20-600 | mm |

| 11 | Main motor power | 55 | kw |

| 12 | Oil pump | 40 | L/min |

| 13 | Measurement | 30m*1m*2m | mm |

| 14 | Weight | 25000 | kg |

| 15 | Voltage | 380V/50Hz/3Phase | v |

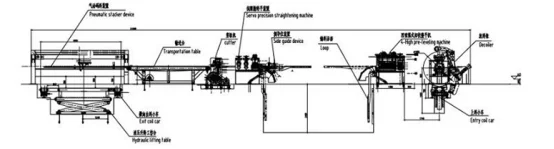

Cut to length machine Working flow

Feeding trolley→ un-coiler→ leading and traction head, pinch roll feeding→ high precision leveling device→ cut to length→ unloading table/auto-stacking table

1. Coil should be put right to keep the weight balanced. The coil car can reset only after fix and expand the coil into decoiler tightly.

2. First press the coil head by traction roll, then open the package of the coil, to prevent the coil head bounced off.

3. Operators shall not stand on the coil when machine running.

4. Do not move coil directly by hand.

5. Stop and check the machine units immediately when find fault. Only check out and correct, the machine can restart.

6. Do not remove or change circuit. In case has problem, please consult professional technicians.

Cutting To Length Machine Product display