Frame rolling shutter door forming machine product description

Video Description

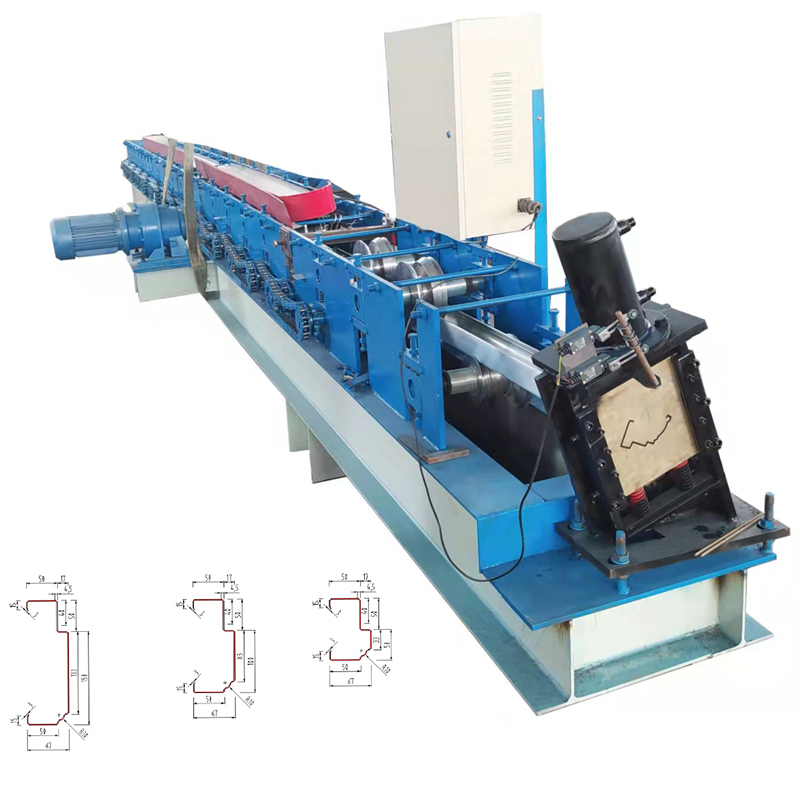

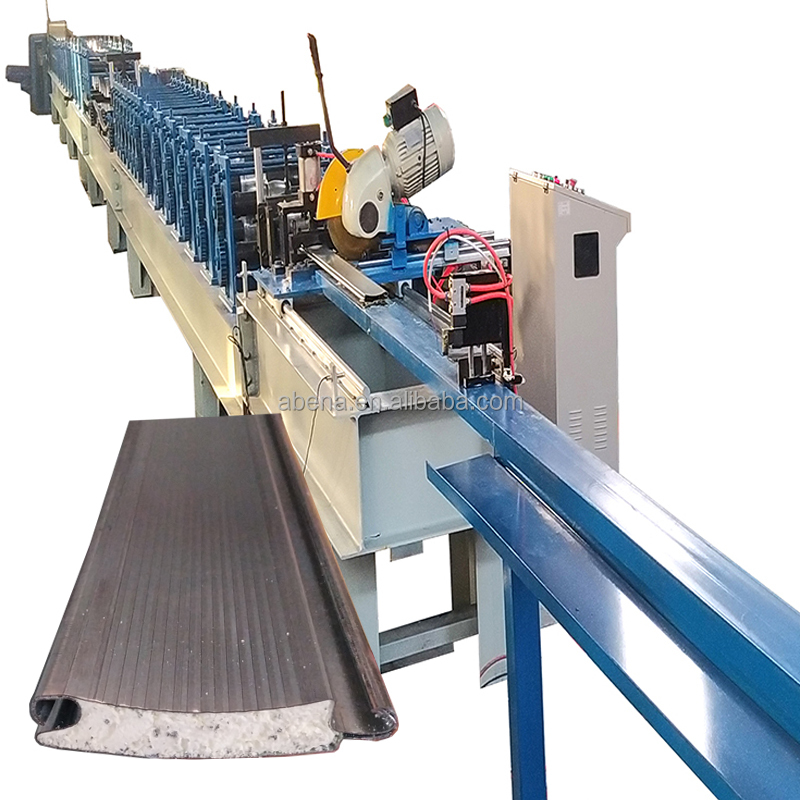

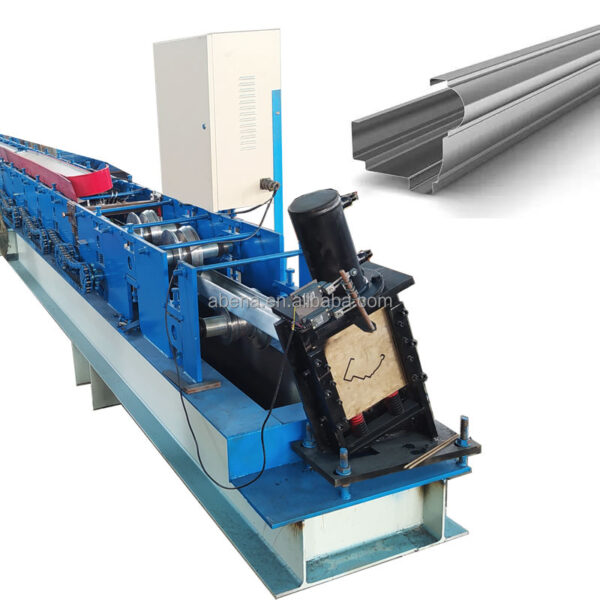

1.This machine is made up of roll forming machine,molding press,cutting machine,PLC computer control and hydraulic system.

2.The machine is stable,no noise,no shake.

3.Controlling by computer,PLC display,operation is easy,running is steady and reliable,endurable,maintenance-free.

4.Cutting machine is characterized by stable driving,easy operation.

5.Hydraulic system use the hydraulic pump,long operating life,no noise.

Product parameter of Shutter Door Machine

| Suitable Material | Colored Steel plate, Galvanized Board,Aluminum Plate |

| Width of the raw material | 170mm |

| Rows of rollers | 12 rows |

| Thickness of raw material | 0.8-1.2mm |

| Diameter of shaft | 38mm |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Warranty | 2 Years |

| Certification | ISO |

| Dimension(L*W*H) | 4500*800*1500mm |

| Voltage | 380V 50Hz 3phases |

| Power(W) | 4kw |

| Use | Door |

Working flow of Roller Shutter Door Machine

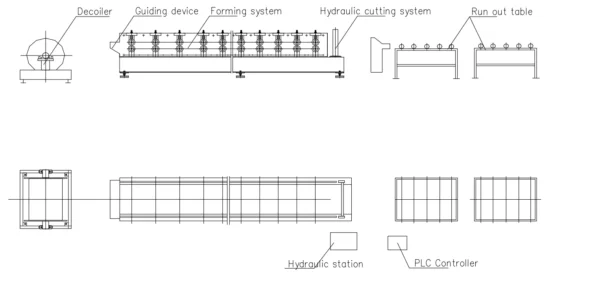

Decoiler-roll forming machine-PLC control box-hydraulic cutter-Run out table

Frame rolling shutter door making machine product

The components of the shutter door machine include: decoiler, roll forming machine body, hydraulic cutting, plc control system, main motor, pump station, receving table.

Equipment features: shutter door machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

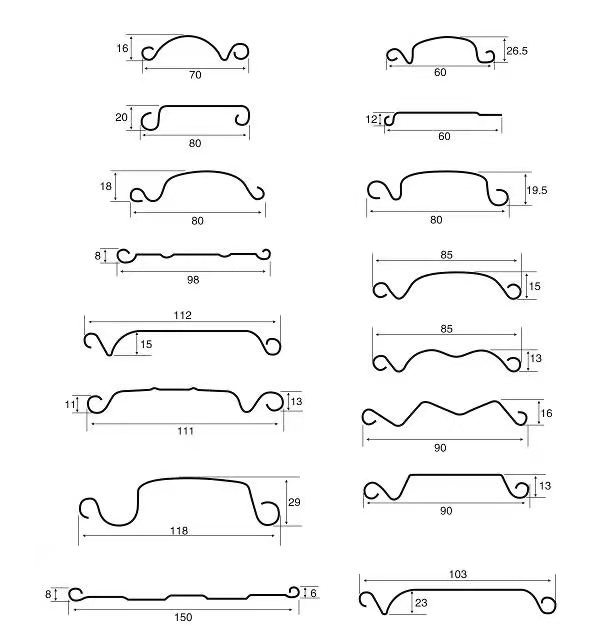

The following styles can be customized