U channel guide rail making machine Product descriptions

Video Description

U guide rail machine is one kind of widely used products, we also named it as U channel track machine, this kind of U guide rail machine are widely used in the door manufacturing. We can produce the U guide rail machine U channel track machine for you, we have almost 20 years experience to produce this kind of roll forming machines. Our steel liner machine customer came from all around the world. Such as Algeria, South Africa, United States, United Arab Emirates as so on. I am sure our machine will let you satisfied.

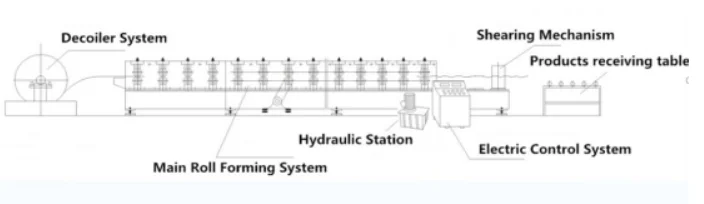

U channel Door Rail Machine of Working flow

Manual Decoiler—Entry Beach—Roll Forming Machine—Automatic Shearing Mechanism—Computer Control Cabinet—Run-out Tables

| Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

| Thickness of coil sheet | 0.3-0.8mm |

| Coil width | 1000/1250mm as drawing |

| Effective width | as drawing |

| Material of main frame | 300-400H steel |

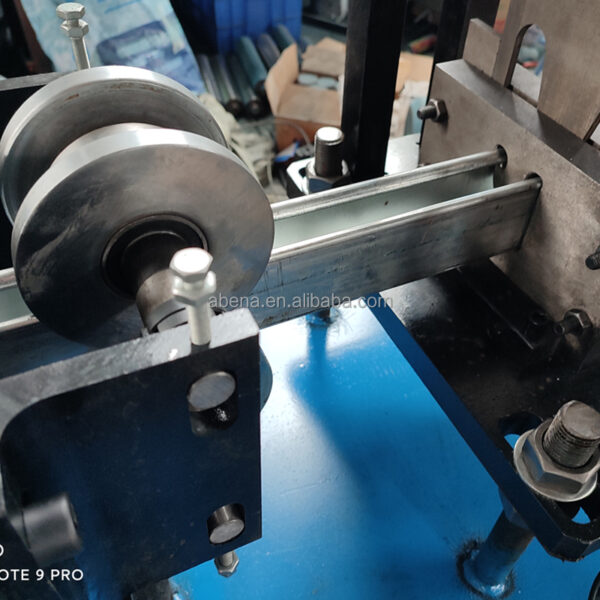

| Diameter of Soild shaft | 75mm, high grade 45# steel |

| Roller | High grade 45# steel, quenched and tempered treatment, hard

chrome plated 0.05-0.07mm |

| Thickness of middle plate | 16mm, 45# steel plate |

| Forming roller station | 13-18 rows |

| Drive type | By chain(1.0 inch), link bearing model 6210 |

| Power of main motor | 5.5 kw, Lichao of Shanghai |

| Sidewall connection bar | 16/18mm, zinc plated |

| Forming speed | About 12-18m/min |

| Hydraulic pump station | 5.5kw, 40# hydraulic oil |

| PLC | DELTA(TAIWAN)/Mitsubishi |

| Material of razor blades | Cr 12, quenching 58-62°C |

| Frequency converter | It has the advantage of slowing down before cutting,

to ensure the length accuracy ±1mm, far better than industrial standard ±3mm. |

| Switch | CHNT |

| Frequency changer | Delta |

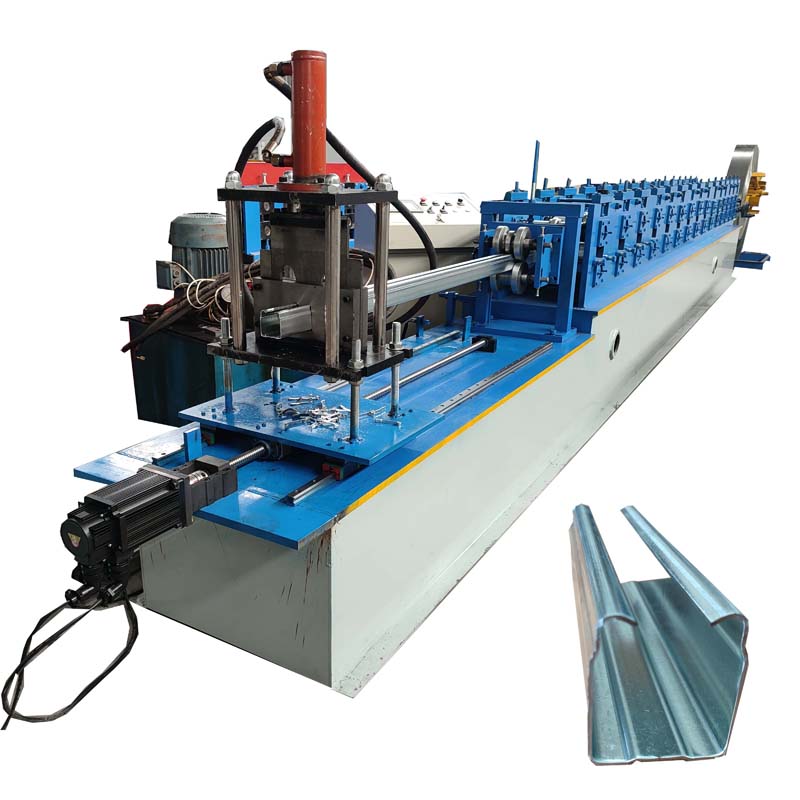

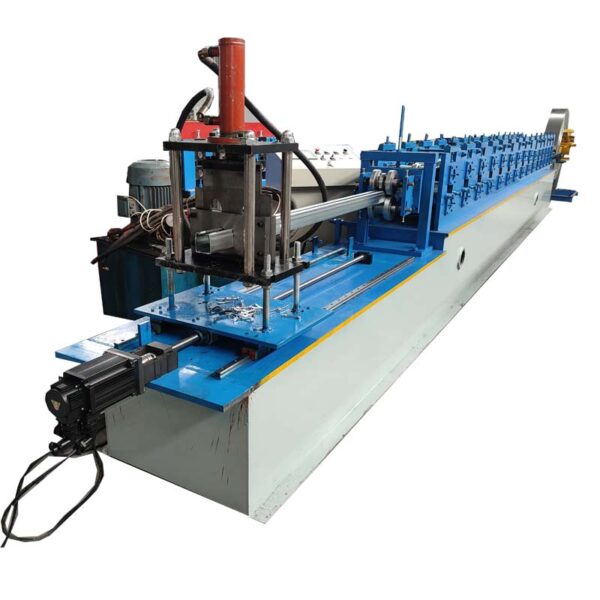

Metal U channel guide rail roll forming machine Product display

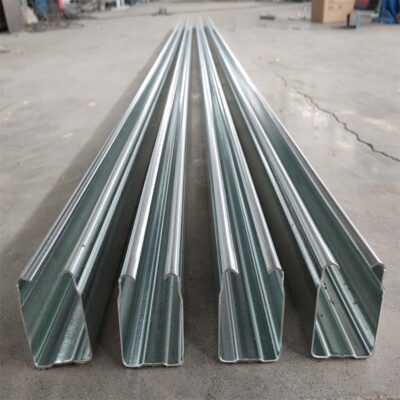

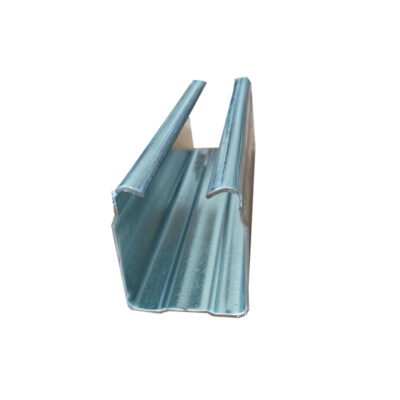

Finished product of U channel Door Rail Machine

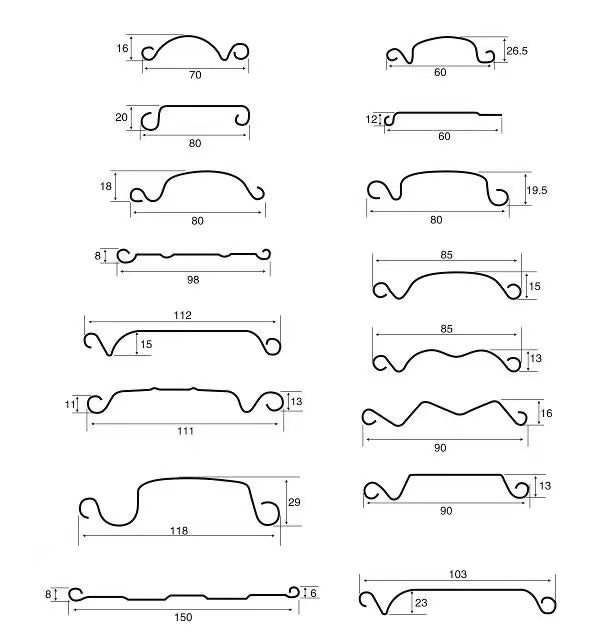

Hot sale drawing profiles showing of U channel Door Rail Machine

Guide Rail Machine Product Features

1. More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chrome plated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.