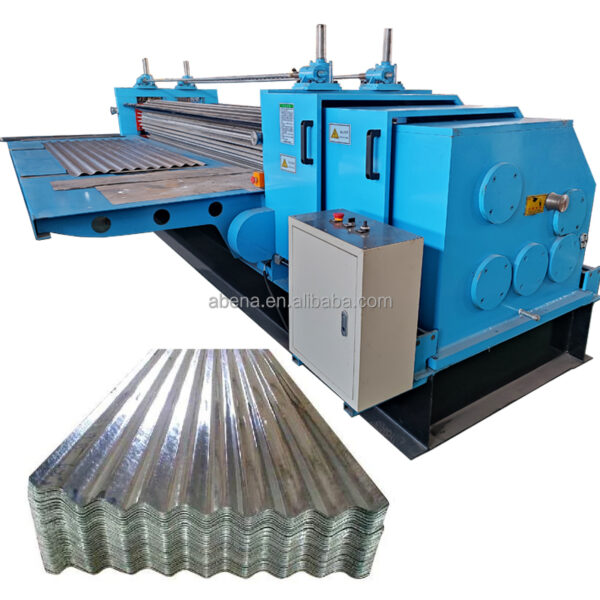

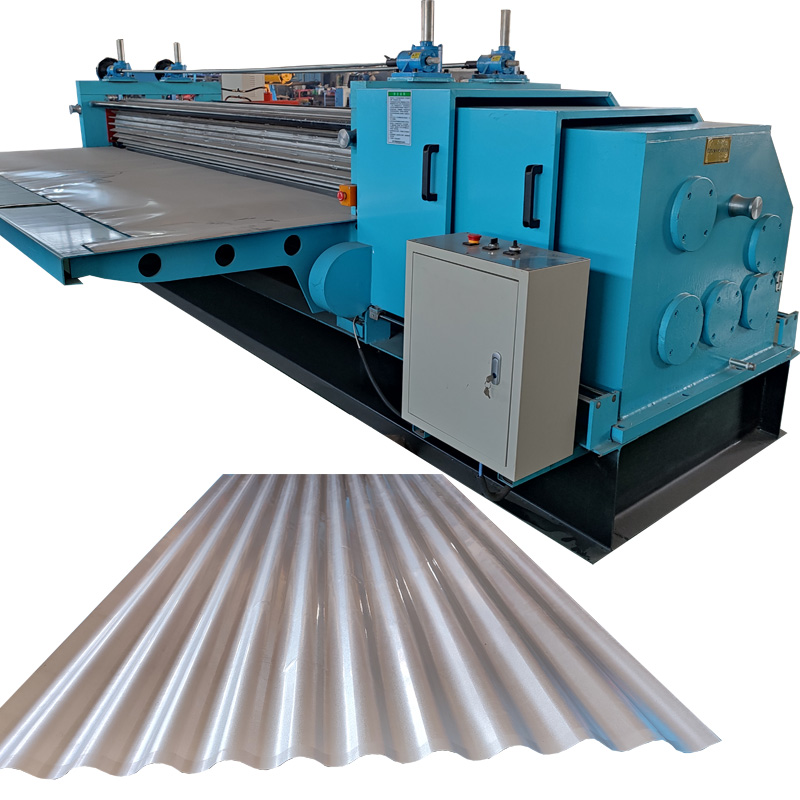

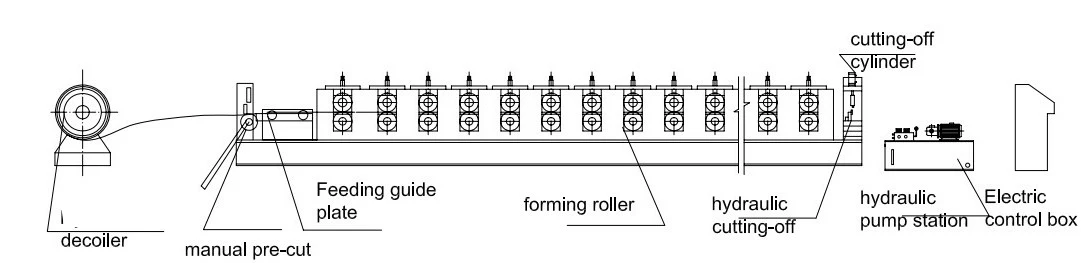

The cylindrical corrugated plate forming machine is used to produce sine wave shaped panels and is specially produced for 0.1-0.5mm high-strength materials. The cylindrical corrugated forming machine is mainly composed of drive motor, reducer, transmission system, forming roller, flat roller, automatic feeding platform, electrical control cabinet, etc. The automatic feeding of the work roller is always carried out by timing chains and linear guides, thus ensuring Product stability, we can customize various equipment for you according to different requirements.

Video Description

Corrugated Roof Making Machine Working flow

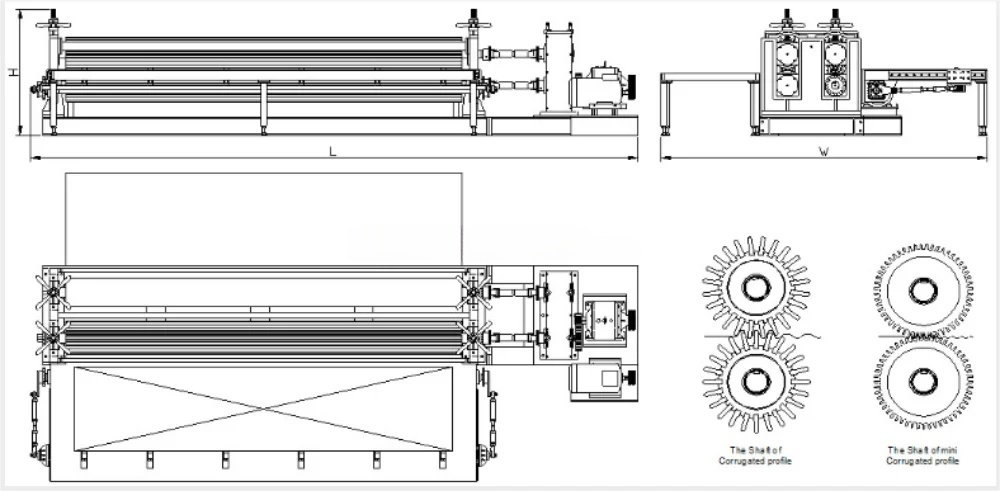

| Main parameter barrel corrugated roll forming machine | |||

|

Forming steps

|

4 piece roller

|

||

|

Shaft diameter

|

340mm

|

||

|

Machine stand

|

Individual Arch Plate

|

||

|

Machine frame

|

steel plate welded

|

||

|

roller material

|

45#steel

|

||

|

shaft material

|

45# steel with quenching and tempering

|

||

|

Work speed

|

15-30 pieces/min

|

||

|

Transport

|

chains

|

||

|

Power of main machine

|

4kw

|

||

|

Voltage

|

380V-50HZ-3P(as required)

|

||

|

Machine dimension

|

5.7*2.0*1.5m

|

||

|

Machine weight

|

About 4.5T

|

||

|

Machine color

|

Yellow and blue(as required)

|

||

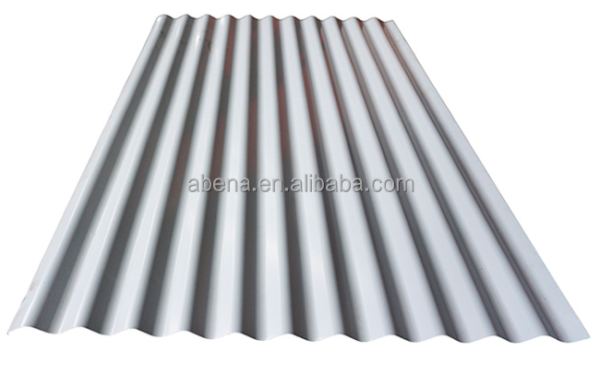

Barrel Corrugated Roll Forming Machine Product Detail

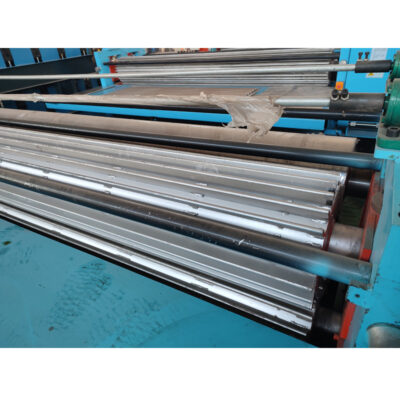

Machine roller and platform

This function is to receive the finished sheets, which is convenient for the workers

The roller is rolling the raw material

The machine shaft

This is the feed roller, which plays the role of leveling the raw material, and it is more smooth when the machine is pressing

The machine PLC

The PLC can set the sheet length, fully automatic

Barrel Corrugated Making Forming Machine Product display

In construction industry we are able to manufacture many more machines like Main Channel Roll Forming Machine, Purlin Roll Forming Machine, Drywall Roll Forming Machine, Stud Roll Forming Machine, Orbit Roll Forming Machine, Metal Floor Deck (Floor deck) forming machine, roof panel/wall panel forming machine, roof tile forming machine, corrugated forming machine, ridge forming machine, etc.