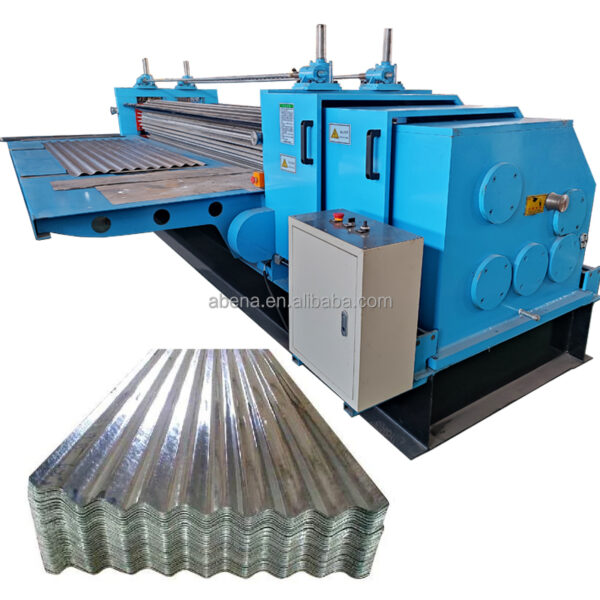

Barrel Corrugated Roof Forming Machine Product Description

Fast Speed:the machine speed is about 20-60 pieces/min,if material very thin,can make 3 pieces at the same time.Forming Thin Material:Thin material such like 0.12-0.3mm thicknessis very popular in Africa market, so this machine is very popular in that market.

|

S.N

|

Description

|

Unit\Type

|

RF-BC

|

|

1

|

Steel Thickness

|

mm

|

0.12-0.3mm

|

|

2

|

Forming Speed

|

m/min

|

2-3 seconds per piece

|

|

3

|

Roller stands

|

stand

|

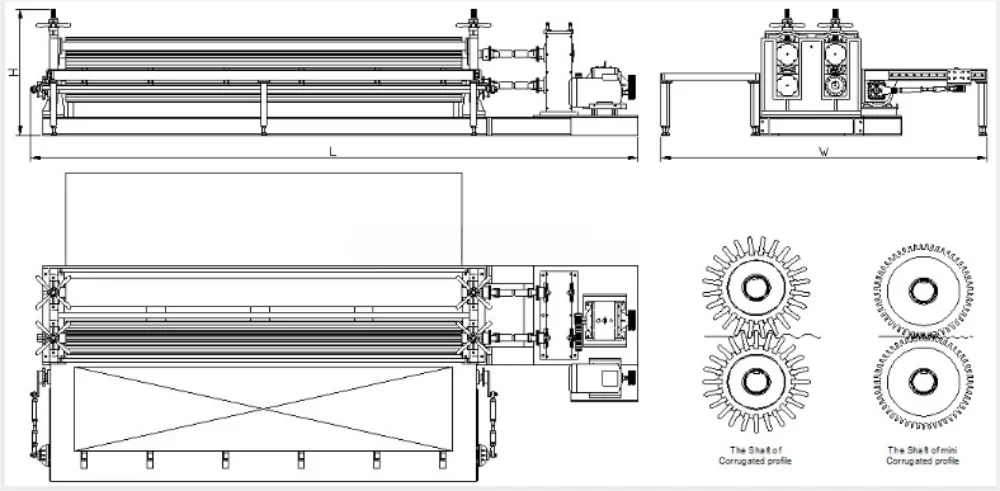

2 set (4 pieces)

|

|

4

|

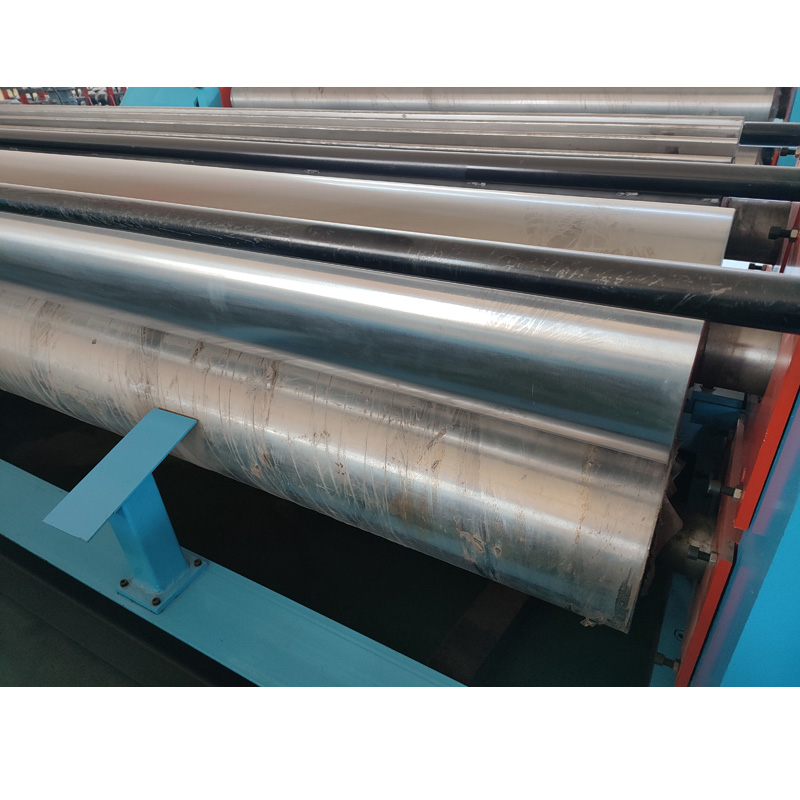

Roller Material

|

|

High grade 45# forged steel

|

|

5

|

Roller diameter

|

mm

|

450

|

|

6

|

Main Motor Power

|

kw

|

7.5

|

|

7

|

Power Supply

|

|

380V, 50HZ,3 phase

|

What is the main diffence between normal vertical design corrugated sheet machine and horizontal barrel corrugated sheet roll forming machine?

Vertical design corrgated roll forming machine use for produce normal strength material, thickness 0.3-0.8 mm.

The corrugated roofing sheet width is fixed, length can be controlled by PLC system, roof sheet quantity also can be set up by your request.

Horizontal barrel corrugated sheet roll forming machine especially produce high strength material 0.13-0.5 mm.

The roof sheet length can be adjust any under the max width you choose, for example, the machine width is 3.6 m, so you can produce any length under 3.6 m.

The corrugated roofing sheet wave height and wave distance can be adjust freely.

For the profile drawing, you can provide or we can recommend you, here have a standard drawing for your reference:

DIfferent market may popular for different width corrugated roofing sheet, so use different coil width.

Firstly you need confirm what width coil normally used in your market, usually have 914 mm, 1000 mm, 1200 mm, 1250 mm.

More machine pictures for your reference:

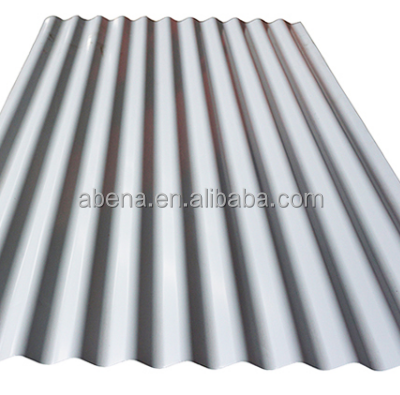

The finished corrugated thin metal roofing sheet: