Floor Deck Roll Forming Machine Description

Composite floor deck is part of a flooring system that is commonly used in commercial and industrial buildings. The decking is typically installed over steel beams, steel joists, or concrete beams and is used for concrete pour applications. The galvanized panels have embossments on the inner face of the panel for concrete to adhere to the panel and become an integral part of the slab. These indentions provide reinforcing value from horizontal forces, increasing the overall strength of the floor. Composite floor deck provides an efficient form compared to wood forms and eliminates the need for temporary installation forms, decreasing time and costs.

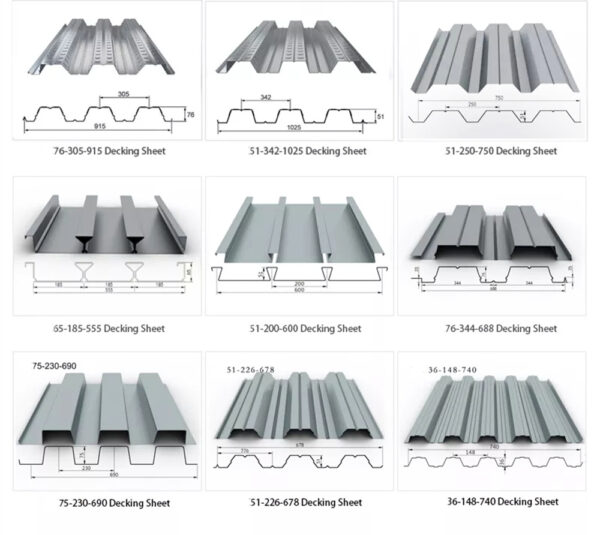

Profile drawing of the floor deck:

video description

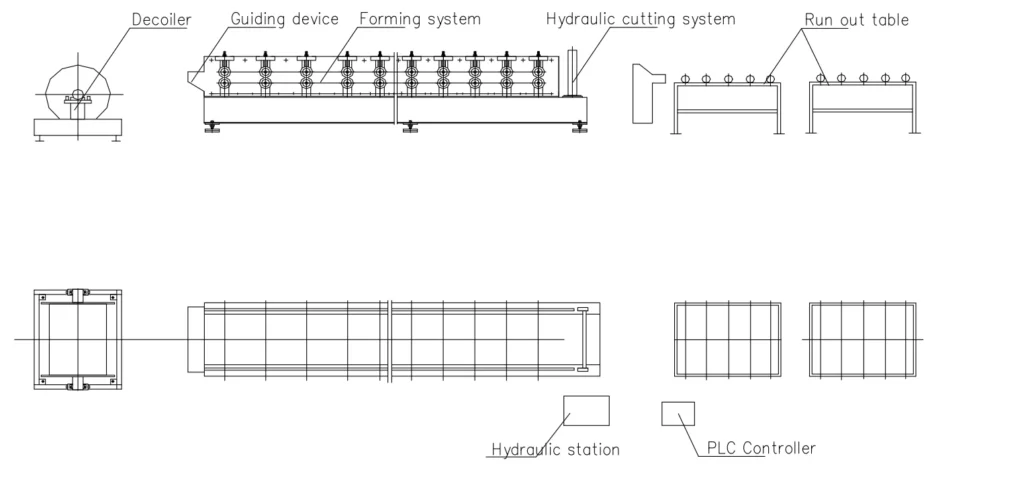

| Manual Uncoiler | 1 set |

| Guiding Platform | 1 set |

| Coil Strip Leveler | 1 set |

| Main Machine of Roll Forming | 1 set |

| Electric-Motor | 1 set |

| Cutting Device | 1 set |

| Hydraulic Station | 1 set |

| PLC Control | 1 set |

| Receiving table | 1 set |

1.Product name: floor deck roll forming making machine

2.main motor power:22kw

3.Production Capacity:12-18m/min

4.Shaft diameter:95mm

5.roll station:27 roller stations

6.cutter material:Cr12

7.Total weight:19 Tons

8.Feeding Width:1000mm/1200mm/1250mm

9.Hydraulic motor power:5.5kw

10.Backboard Thickness:22mm

Floor deck machine flow chat

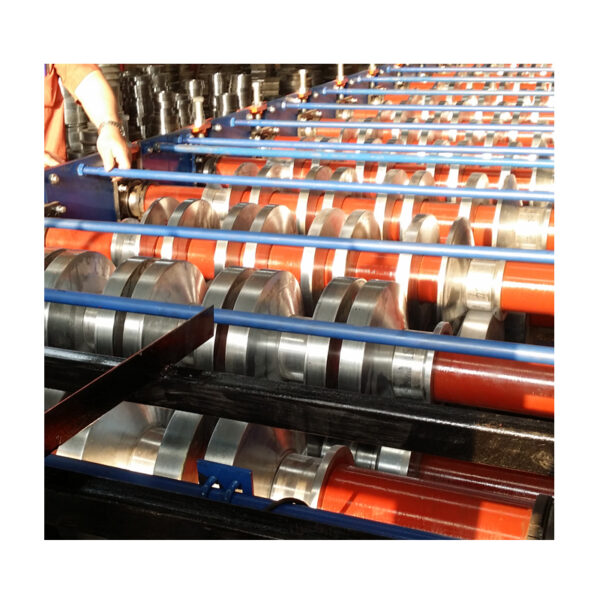

Floor Deck Making Machine Details

Name: Cutting head

1.Material is Cr12

2.Guide post:45#steel Quenching is done before heat treatment,can guarantee the surface smoothness and hardness.

Hydraulic oil: 46#

Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa