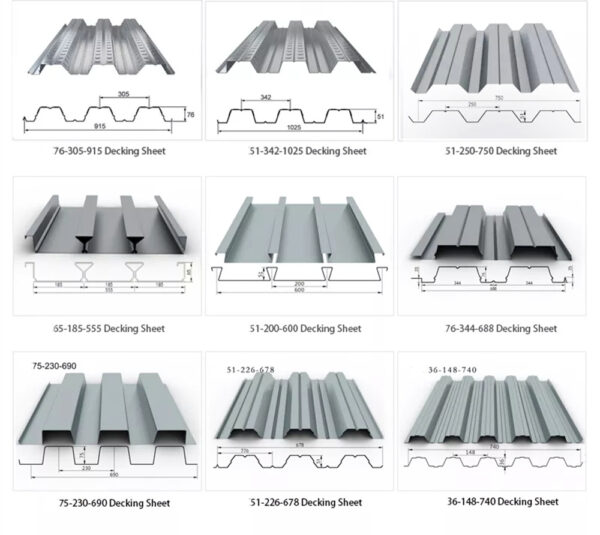

Decking Forming Machine Production Description

Video Description

Composite floor deck is part of a flooring system that is commonly used in commercial and industrial buildings. The decking is typically installed over steel beams, steel joists, or concrete beams and is used for concrete pour applications. The galvanized panels have embossments on the inner face of the panel for concrete to adhere to the panel and become an integral part of the slab. These indentions provide reinforcing value from horizontal forces, increasing the overall strength of the floor. Composite floor deck provides an efficient form compared to wood forms and eliminates the need for temporary installation forms, decreasing time and costs.

|

Product Specification of Floor Deck Roll Forming Machine

|

||

|

No

|

Item

|

Data

|

|

1

|

Raw material width

|

1000-1200 mm

|

|

2

|

Sheet effective width

|

750-1000 mm

|

|

3

|

Raw material

|

Color steel sheet or galvanized steel sheet

|

|

4

|

Material thickness

|

0.3-0.8 mm or customized

|

|

5

|

Forming roller material

|

45# steel plated with chrome

|

|

6

|

Shaft diameter

|

70 mm

|

|

7

|

Forming roll station

|

8-16 steps

|

|

8

|

Main motor power

|

3 KW 4 KW 5.5 KW(according to type)

|

|

9

|

Hydraulic power

|

4 KW (according to type)

|

|

10

|

Control system

|

PLC control

|

Floor Deck Making Machine Product Display

main features of Decking Roll Forming Machine

1: Adapting to the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short period of time, and can use multiple floors to lay profiled steel plates and layered pouring of concrete slabs for flow construction.

2: During the use stage, the floor support plate serves as the tensile steel bar for the concrete floor slab, which also improves the stiffness of the floor slab and saves the amount of steel and concrete used.

3: The surface embossing of the profiled plate creates the maximum bonding force between the floor bearing plate and the concrete, forming a whole between the two. With the addition of stiffeners, the floor bearing plate system has a high-strength bearing capacity.

4: Under cantilever conditions, the floor support plate is only used as a permanent template. The length of the cantilever can be determined based on the cross-sectional characteristics of the floor support plate. In order to prevent the cracking of the cantilever plate, negative reinforcement shall be provided at the support according to the design of the structural engineer.

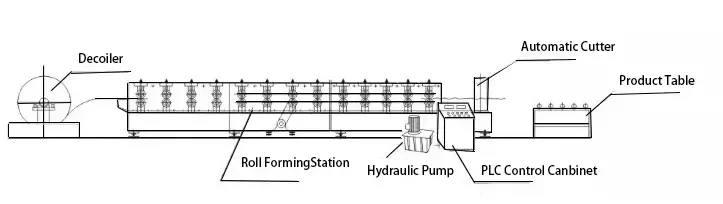

The Working Flow of Decking Roll Forming Machine

Layout Flow for Building Materials Floor Deck Panel Making Machine Steel Floor Deck Roll Forming Machine