Shutter door roll forming machine is widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center. It has many advantages, such as easy installation, short building period, beauty, light weight but high strength.

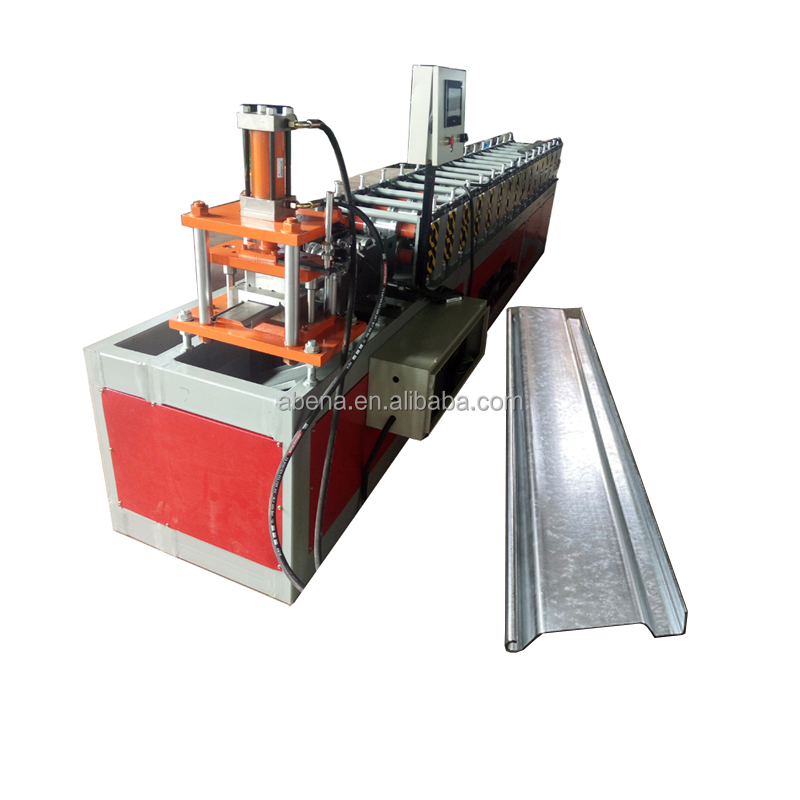

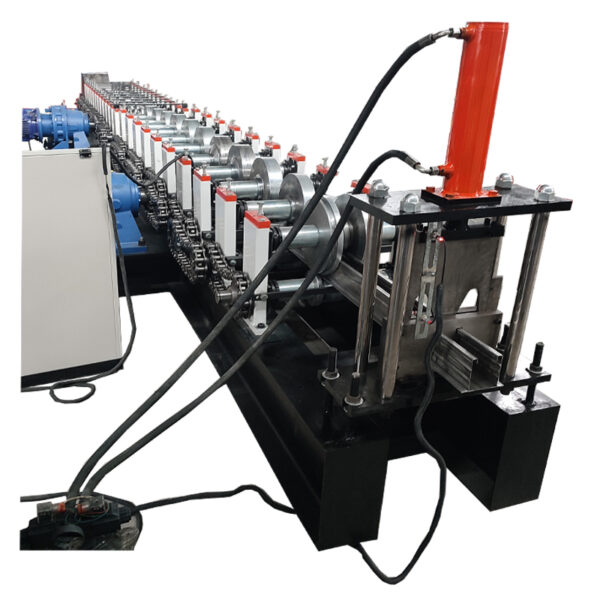

Shutter door roll forming machine Product display

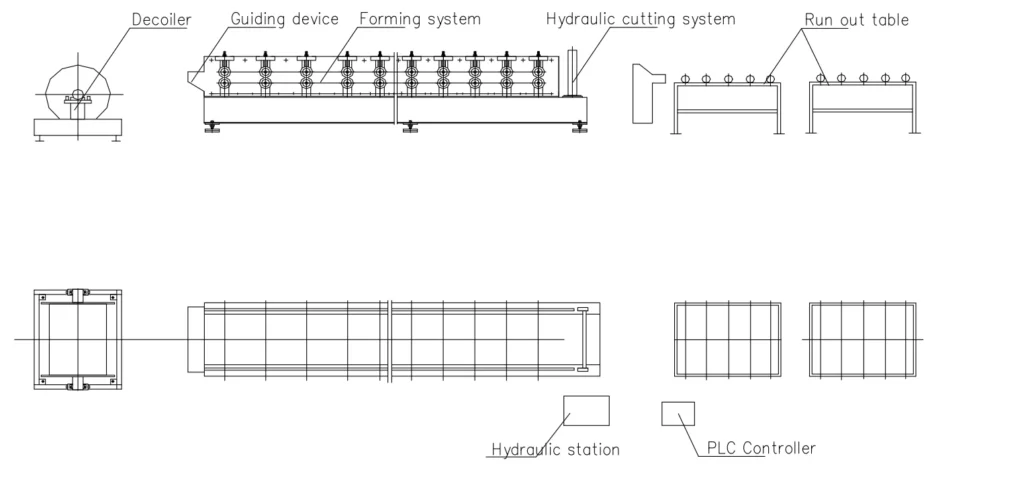

Metal Door Frame Machine Working flow:

Decoiler—→Level device—→Main roll forming machine—→Hydraulic punching—hydraulic cutting→ Run out table

Finished product

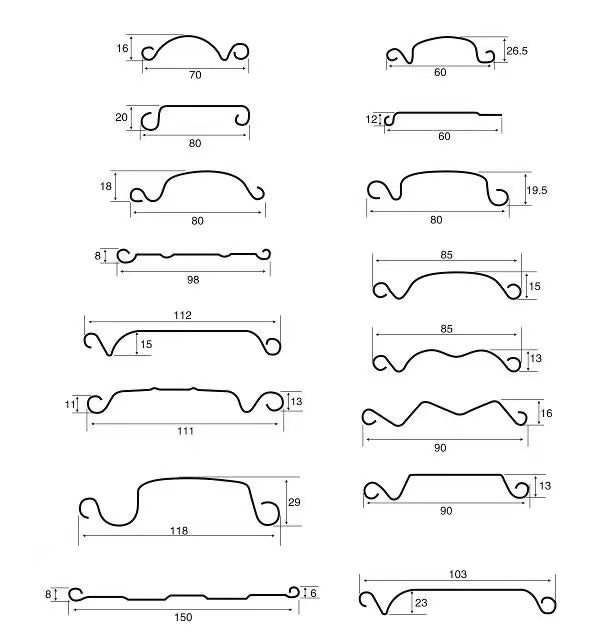

We are the professional shutter door roll forming machine manufacturer in China, we ship shutter door roll forming machine all over the world like India, Thailand, Russia, Algeria, Qatar, Morocco, Saudi Arabia, Oman etc. Common shutter door rolling thickness from 0.7-1.2 mm, material use PPGI or GI. Size can customize as customer’s need.

|

Item |

Name |

Description |

|

1 |

Decoiler |

Capacity:5 tons |

|

2 |

Material |

Steel Coil |

|

3 |

Thickness |

0.3-1.5mm |

|

4 |

Transmission |

Chain/Gear/Gearbox |

|

5 |

Speed |

25m/min |

|

6 |

Roller |

Steel with quenched treatment,chromed on the surface |

|

7 |

Shaft |

steel with tempering treatment |

|

8 |

Cutting type |

Hydraulic cutting |

|

9 |

Cutting material |

Cr12 with quenched treatment Hardness58°-62° |

|

10 |

Welding |

Automatic spot welding |

|

11 |

Control system |

PLC |

|

12 |

Electric brand |

Delta,Siemens,Schneider |

|

13 |

Voltage |

380V,50HZ,3PH(or as customers’ request) |

Application Scenario of Shutter door bottom slat machine

We provide customization for the following versions, or you can customize your own products.