The NC series pipe bending machine equipped with NC controller. It combines easy-to-use operation with high bending accuracy and cost effectiveness. It is the practical semi-automatic solution for small to medium productions. The machine is suitable for various materials such as steel, stainless steel, aluminum and copper.

Tube Machine Product descriptions

Video Description

2. Adopting touched operation panel by single chip computer control man-machine conversation operation, very convenient.

3. The angle of bending uses encoder tracking and give a feedback with a high bending precision.

4. With automatic counting and power-off memory function.

5. Equipped with water cooling system to ensure the stability of the machine for a long time.

|

Type of Equipment

|

63

|

80

|

100

|

125

|

|

Max Tube Specification

|

50*50mm

|

80*80mm

|

100*100mm

|

100*100mm

|

|

Max Processing

Wall Thickness

|

1.0mm(Stainless Steel)

1.2mm(Copper,Alum,Iron)

|

1.5mm(Stainless Steel)1.8mm(Copper,Alum,Iron)

|

1.8mm(Stainless Steel)2.5mm(Copper,Alum,Iron)

|

3.0mm(Stainless Steel)3.5mm(Copper,Alum,Iron)

|

|

Punch Specification

|

3.5-15mm

|

3.5-20mm

|

3.5-30mm

|

3.5-40mm

|

|

Power Spesification

|

380+10V 50HZ

|

|||

|

Total Power

|

3KW

|

4KW

|

5.5KW

|

7.5KW

|

|

Max Working Pressure

|

80Mpa

|

100Mpa

|

150Mpa

|

200Mpa

|

|

Size

|

500*810*1360mm

|

500*810*1360mm

|

580*810*1400mm

|

650*950*1500mm

|

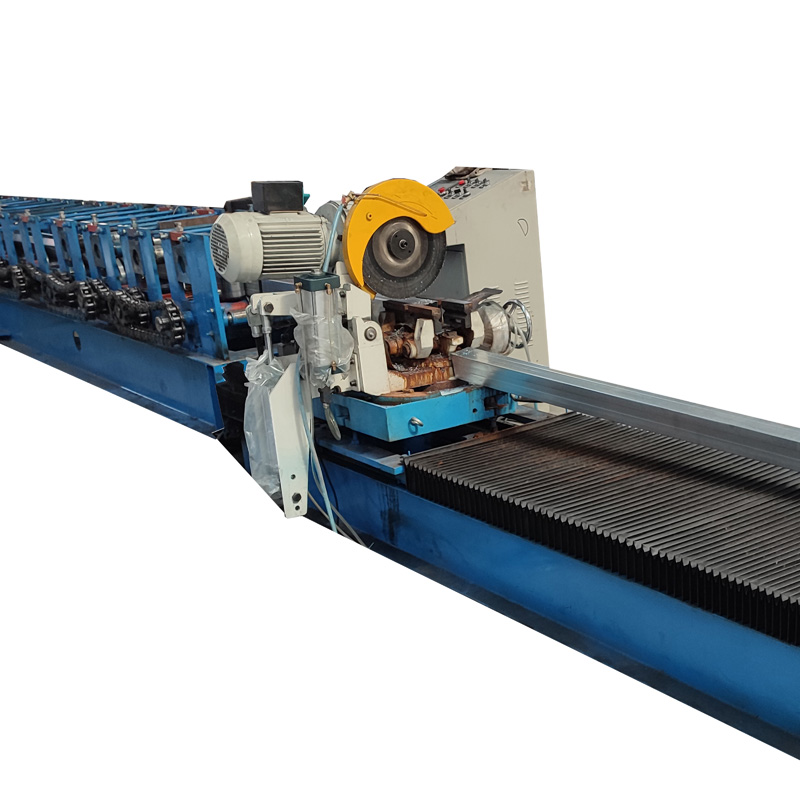

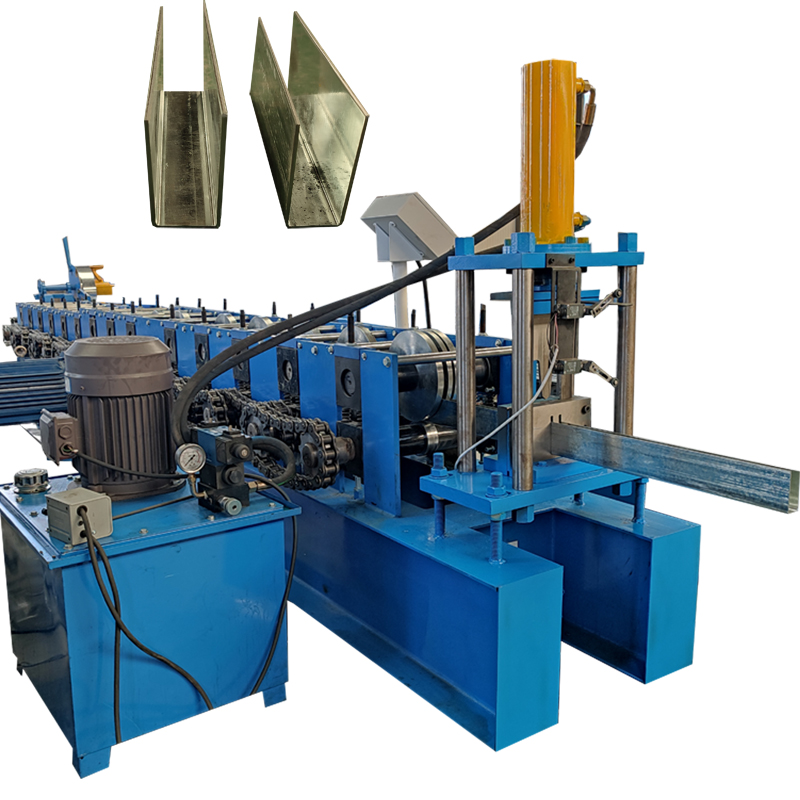

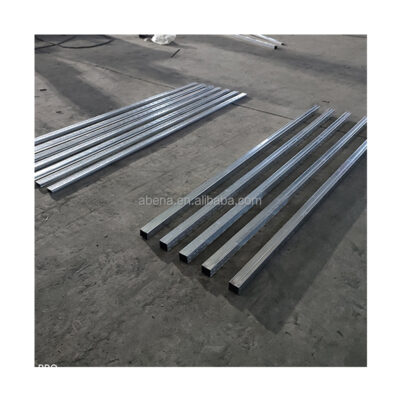

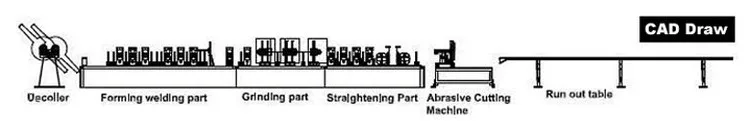

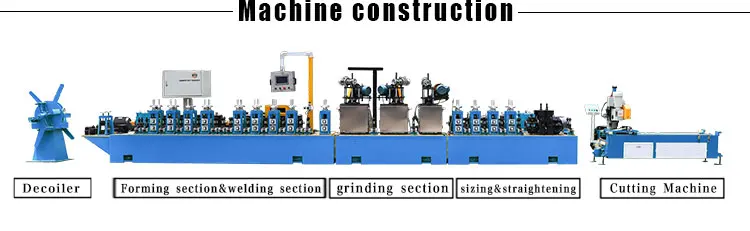

Tube Making Machine Product display

Widely used in door flower, aluminum alloy door and window, stainless steel stair handrail, anti-theft net, guardrail, shelf, zinc steel protective fence, display rack, hardware bathroom, clothes rack, communication antenna rack, furniture, expansion door,building accessories, greenhouse shed, municipal construction, sports equipment, automobile, motorcycle, bicycle, stainless steel decorative products, steel structure angle iron and other pipe or profile punching Hole, oblique arc, cutting processing.