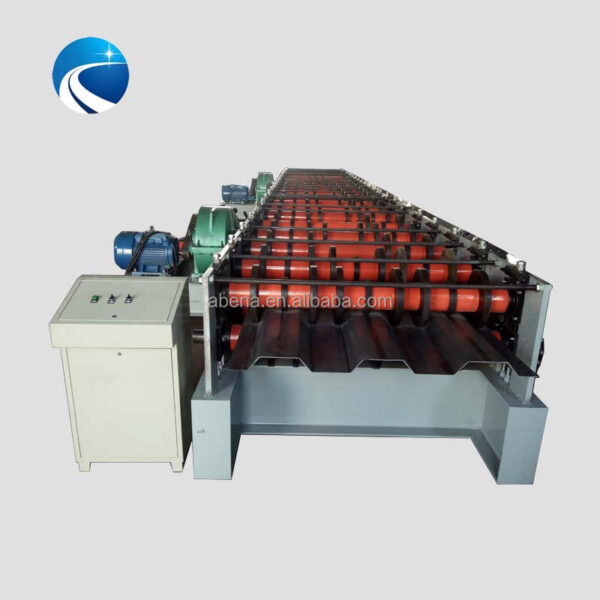

bottom plate roll forming machine Video Description

bottom plate roll forming machine Video Description

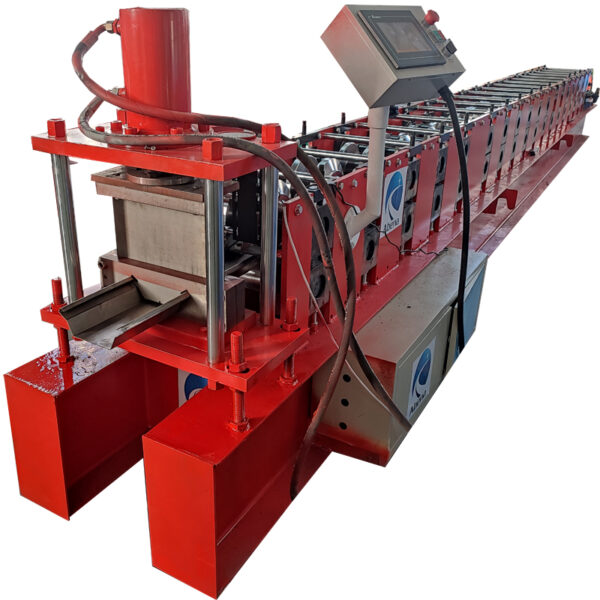

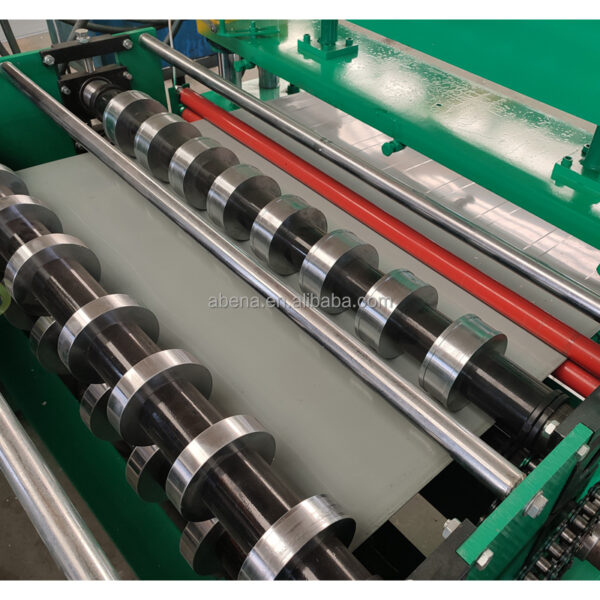

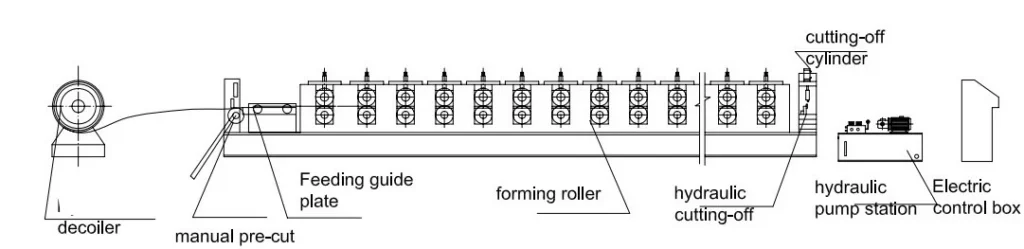

1.The machine has waste coil collection part. The slitting blade in the machine will slit the extra material if the coil is too wide.

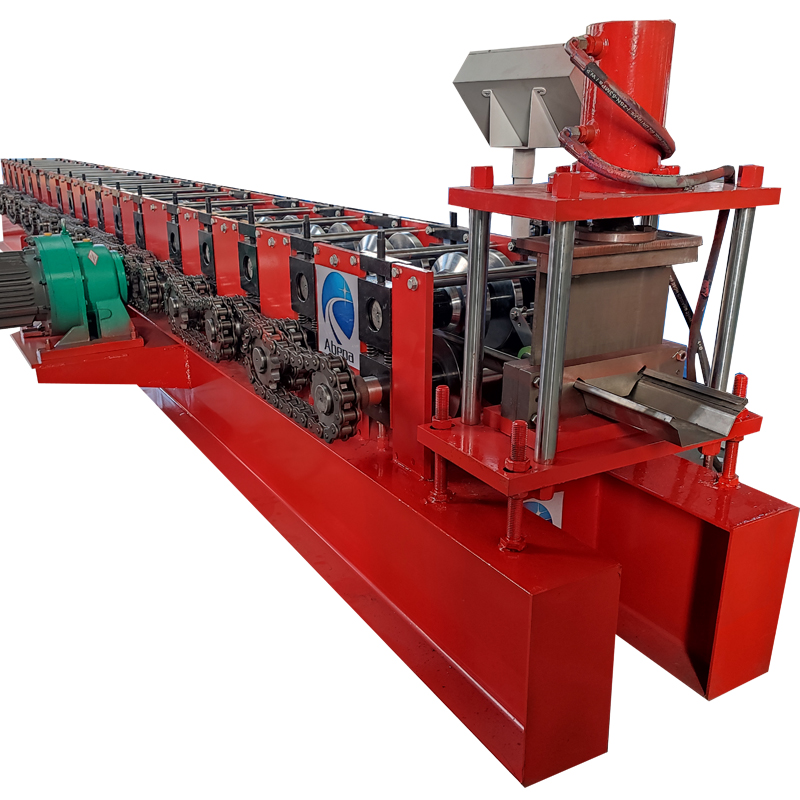

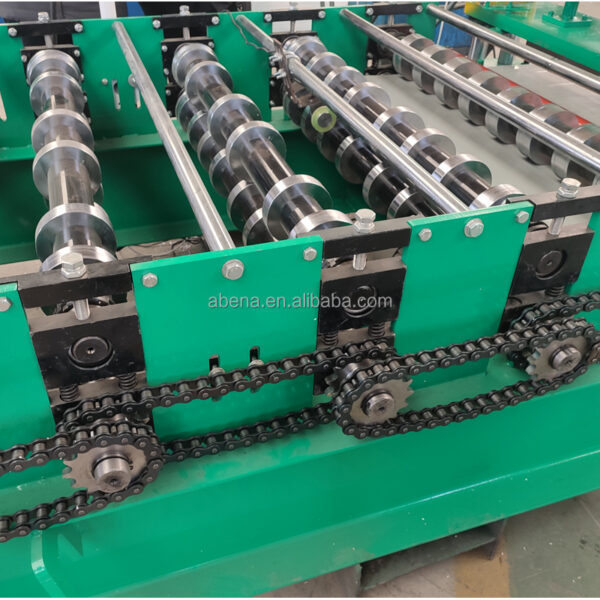

2.For the transmission, we use the double chain. Gear and double chain drive, strong and stable.

bottom plate roll forming machine Parameters

| Sandwich bottom Panel Roll Forming Machine roof panel machineRaw material | Galvanized steel and Pre-painted steel |

| Raw material thickness | 0.3-0.6mm(thickness range shouldn’t be too big) |

| Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| Roller station | 13 stations |

| Roller material | 45# steel with quenched treatment |

| Shaft diameter | 80mm |

| Shaft material | 45# steel with tempered |

| Transmission | by chain |

| Motor power | 5.5kw |

| Machine frame | 350H steel welded |

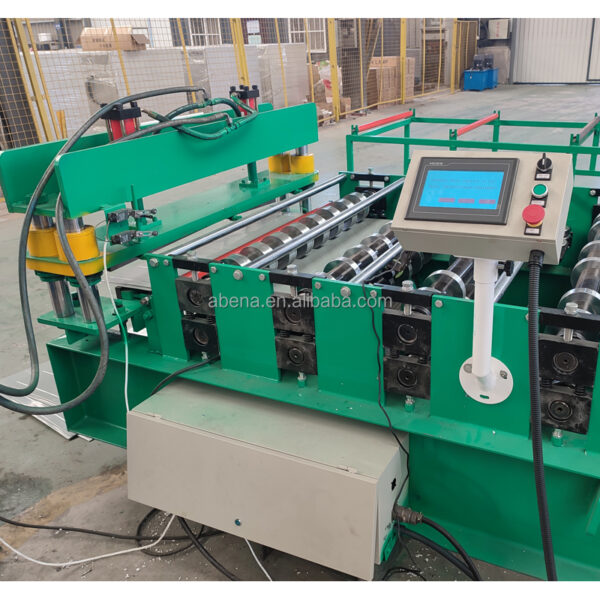

| Cutting type | Hydraulic cutting |

| Hydraulic power | 5.5kw |

| Cutting blade material | Cr12 with quenched treatment |

| Cutting tolerance | +/-1mm |

| Control system | PLC |

Product Display Of Bottom Panel Roll Forming Machine

This machine also can produce our new filmed material which can replace the sandwich panel but the cost is much lower.

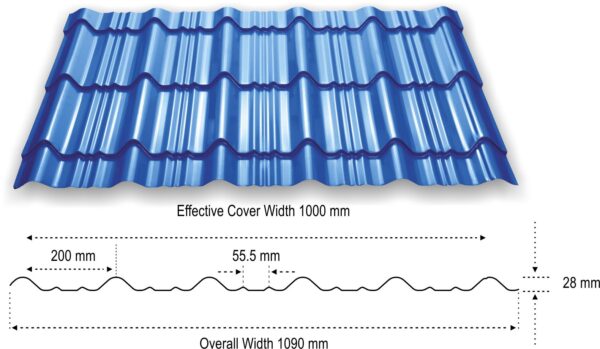

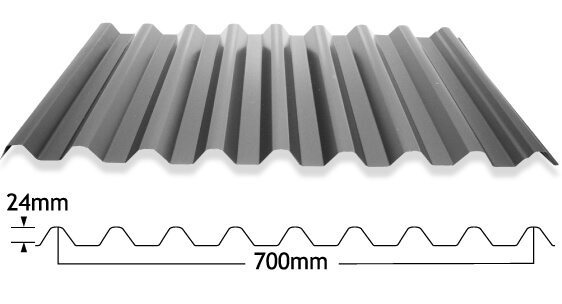

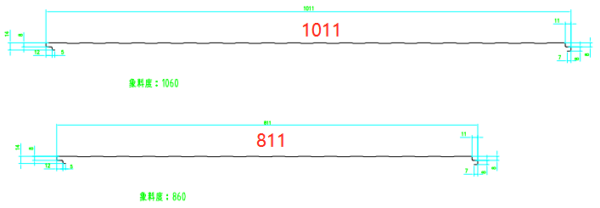

Profile drawing for reference:

Other Design

We have many design drawings to choose from, and of course, you can also provide your unique solutions and support customization. We will provide you with professional advice and produce for you. You can choose to browse the designs and feel free to contact us if you are interested.