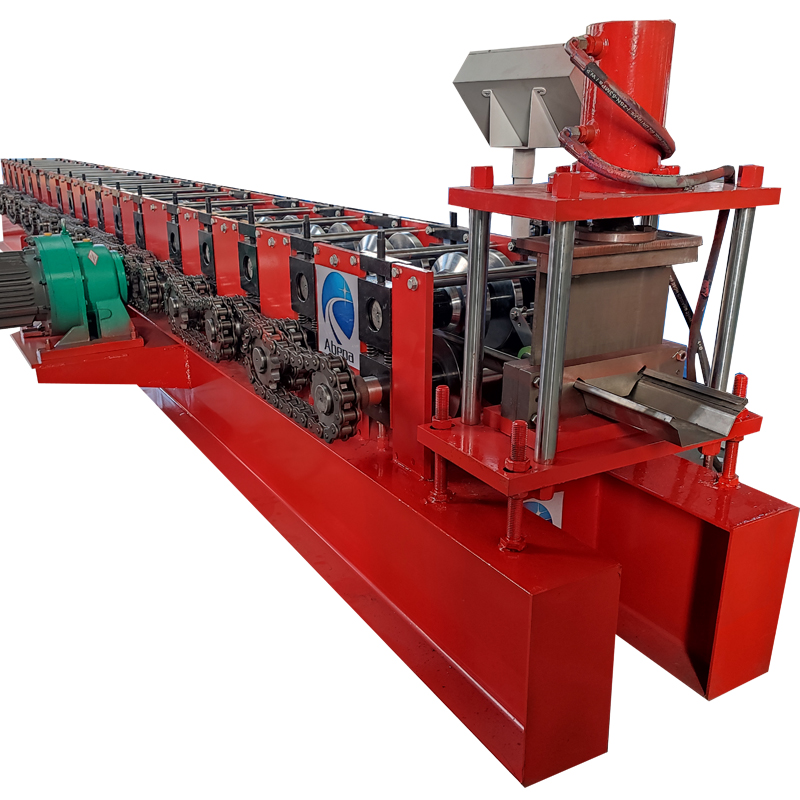

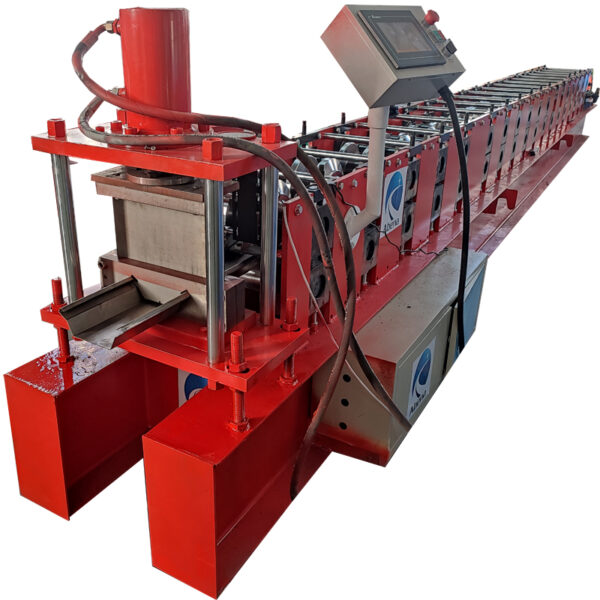

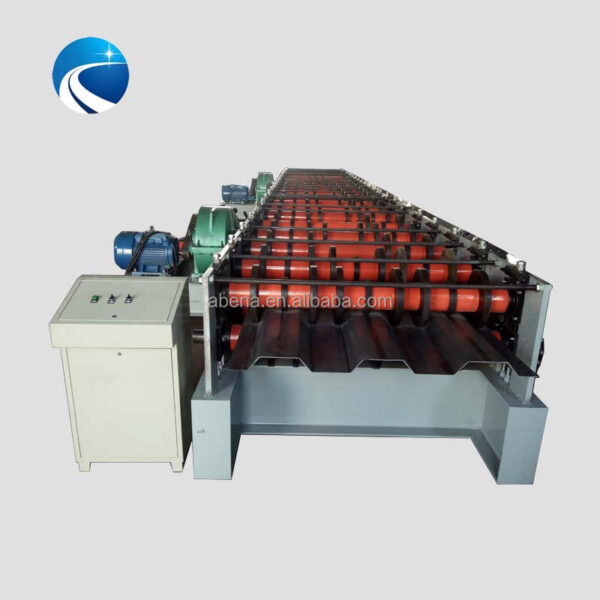

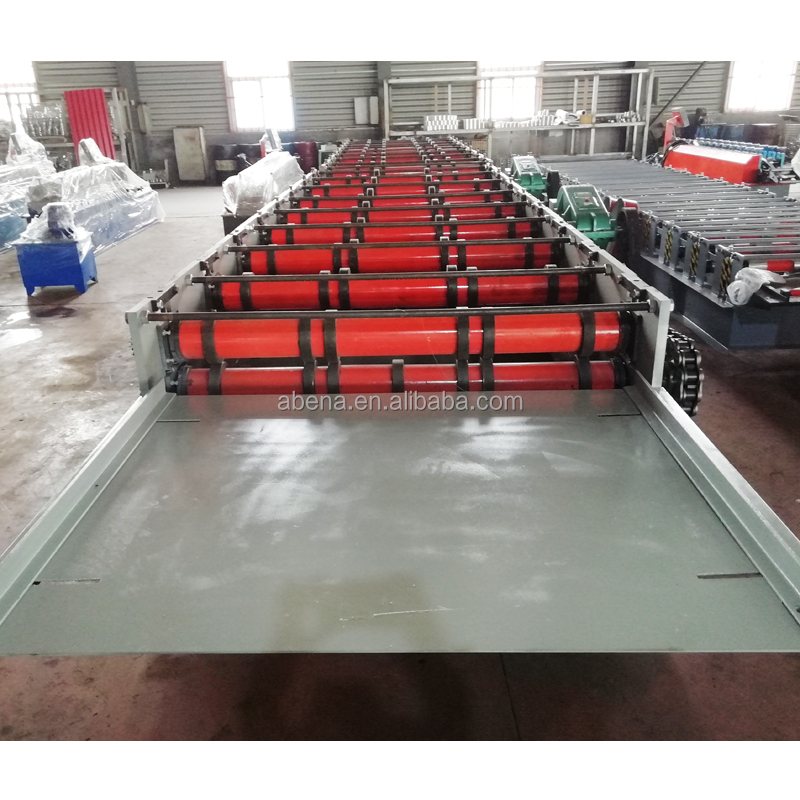

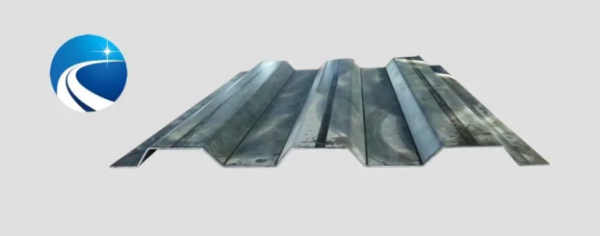

The carriage board machine is mainly used to produce carriage boards, container boards, etc. It is designed and customized according to the thickness, width and peak height of the board. Carriage Panel The roof, front panel, side panels, and door panels are all made of the internationally popular new fiberglass panels for the inner and outer skins of the compartment walls. The middle layer is a new type of fluorine-free polyurethane foam material, which is connected to the skeleton through high-strength adhesives and screws.

Car Panel Making Machine Products Overview

video description

|

Main parameter of car carriage roll forming machine

|

|

|

reduction gears

|

planetary cycloid reducer

|

|

gauge of plate

|

18mm

|

|

chain wheel

|

2 inch; G chromium 15 bearing steel finish car, polished hard chromium plating 0.05mm

|

|

main axis

|

material 45# steel, axle diameter 100, after quenching and tempering treatment

|

|

Roll mould

|

45# steel forgings, roughed by ordinary lathes, CNC lathes, heat treatment, polishing, hard chrome plating

|

|

Roll row number

|

22 row stations

|

|

frame

|

400 GB I-beam

|

|

rolling plate thickness

|

0.8-1.5mm

|

|

Rolling feeding speed

|

(6-10) m/min

|

|

control system

|

computer control plate length machine plate number

|

|

hydraulic power pack

|

motor power 7.5kw

|

|

main motor power

|

11kw*2sets

|

|

dimension

|

14*1.5*1.3m

|

|

weight

|

15 tons

|

The finished equipment is mainly used for collection boxes, simple container rooms, and logistics container trucks.