Car Board Roofing Machine Product Overview

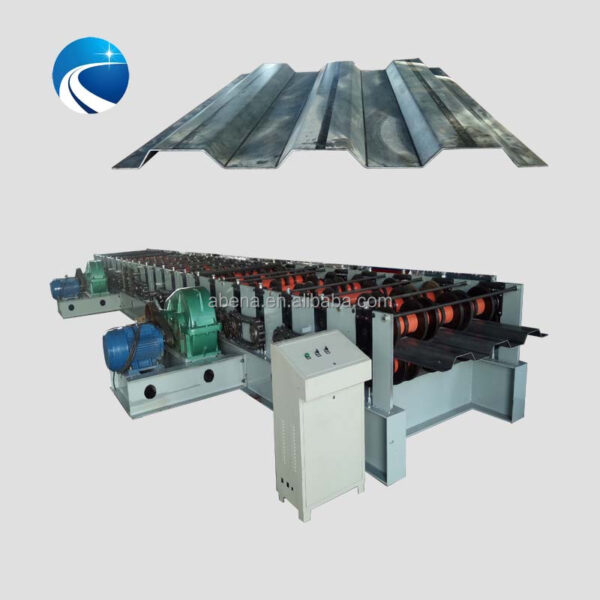

The Roll Forming Machine is composed of feeding, forming, and post-forming cutting. The plate produced has a flat and beautiful appearance, high strength, and durability. It is widely used in industrial and civil buildings, such as factories, warehouses, gymnasiums, exhibition halls, theaters, etc. House surfaces and walls.

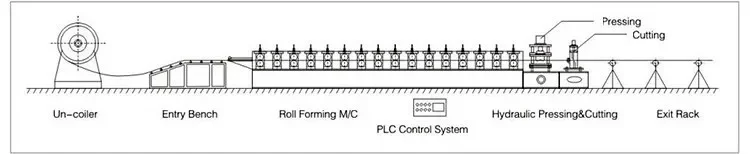

Working Flow of Car Board Roofing Machine

Uncoiling — Sheet guiding — Roll forming — Measure length — Pressure pattern — Cutting — Panels to product stand

easy to operate;long warranty ;security framework; Good value for money; Good quality

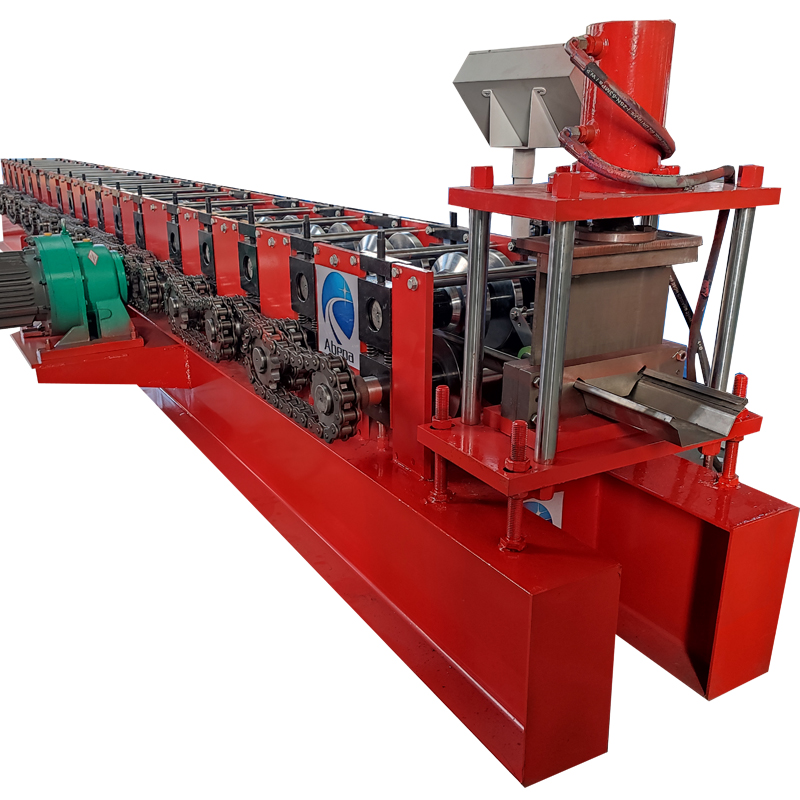

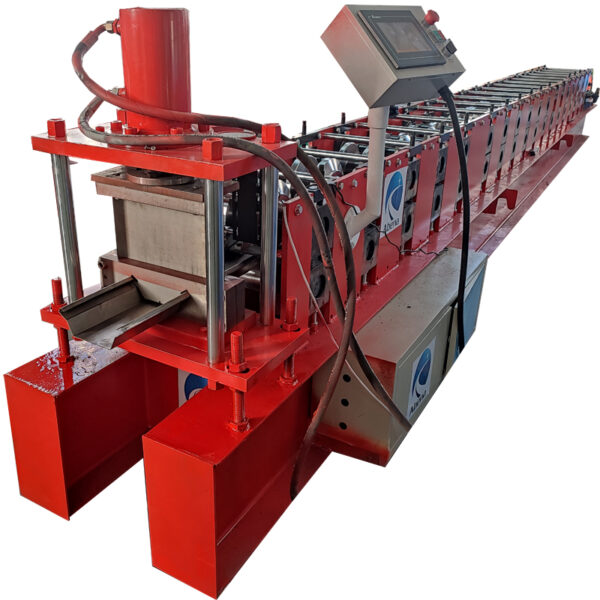

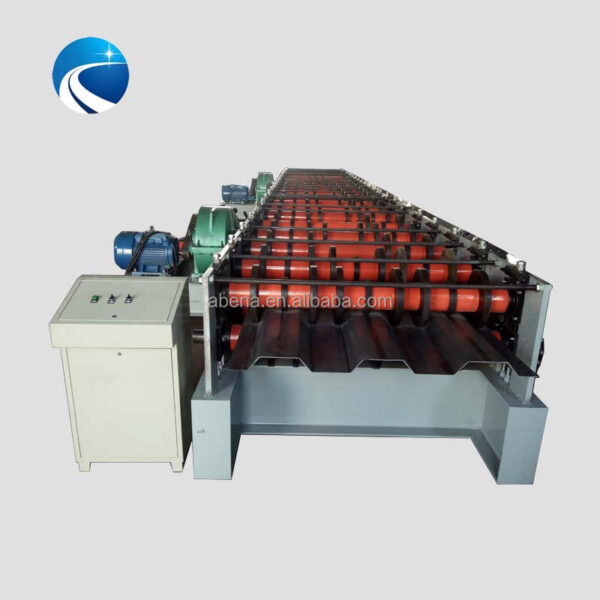

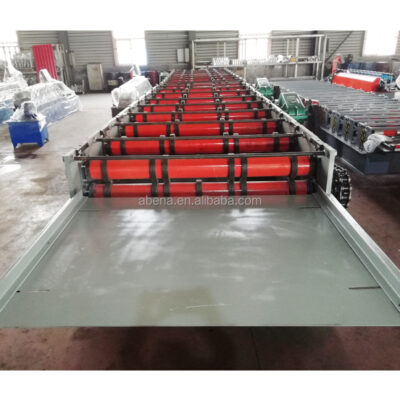

Car Carriage Panel Board Roll Forming Machine Product Display

Car Board Roofing Machine of Product parameters

|

No

|

Item

|

Data

|

|

1

|

Coil Width

|

according to drawings

|

|

2

|

Diameter of shaft

|

70mm

|

|

3

|

Forming Speed

|

8-12meters/min

|

|

4

|

Middle plate

|

16mm

|

|

5

|

Material of shaft

|

45#steel with tempering

|

|

6

|

forming thickness

|

1mm-2mm

|

|

7

|

material of rollers

|

45#steel

|

|

8

|

Cutting type

|

hydraulic -cutting

|

|

9

|

Main power

|

4kw+3kw

|

|

10

|

Main frame

|

300H steel

|

|

11

|

Control system

|

PLC

|

|

12

|

Brand of electrical parts

|

Delta

|

|

13

|

Manual decoiler

|

5 tons

|

|

14

|

Power

|

3 Phase,380 Voltage,50Hz

|

|

15

|

Dimensions(L*W*H)

|

About 6.5*1.2*1.2M

|

|

16

|

Weight

|

about 3 tons

|

Machine Feature of Car Board making Machine

1.Precise forming

2. High-solid forming stand guarantees the goods and uniform high quality of final produced

3. The operation automatically minimizes the tolerance of cutting length

4.Machine with Draw knife that can make the last board without manual cutting and clutch,That can control the number plate.