Leveling and cutting machine is also called a straightening machine or a leveling machine, which is placed between the material rack (or cutting and welding machine) and the feeder, and is used for leveling and feeding of the coil. It is a commonly used equipment in sheet metal processing. The shaping of the leveling machine mainly depends on the thickness, material and requirements of the strip to be calibrated. The thicker the material, the better the structural rigidity. The fewer the number of rolls, the larger the roll diameter, and the power bigger. The leveling machine is mainly used for correcting various specifications of plates and cutting into blocks. This machine is suitable for the leveling of various cold and hot rolled plates. Because of its convenient and simple operation, its application range covers many industries such as machinery, metallurgy, building materials, chemicals, electronics, electric power, light industry, etc., especially in shipbuilding, rolling stock, boiler bridges, metal structure factories and other industries, becoming indispensable in production Essential products.

Steel coil leveling cutting machine Video Description

We can design and make Different width thickness coil cut to length pieces roll forming machine for you.

This machine is 1800mm width and max 3mm thickness galvaized coil cut to length roll forming machine.

Metal Sheet Leveling Slitting Cutting Machine Product Display

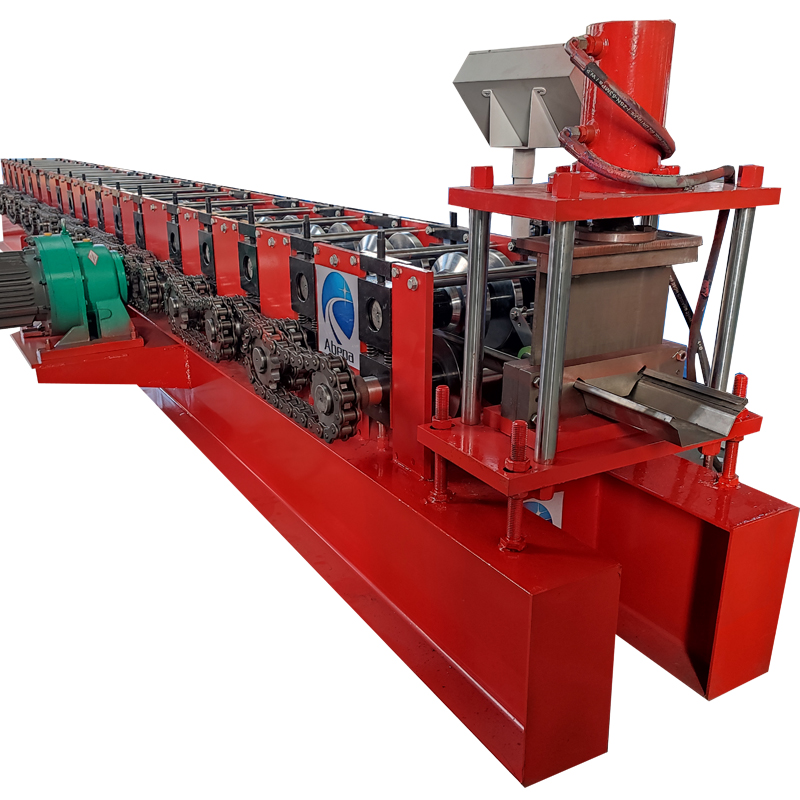

Machine Frame

1. Frame: welded with 300/350/400H steel 2. Forming machine guide feeding rack form: lateral wall panel type 3. Forming machine

form: wall plate type chain drive, the thickness of the middle plate is 14mm. 4. Shaft diameter: ¢70 shaft 5. Sprocket chain: 1.0

inch

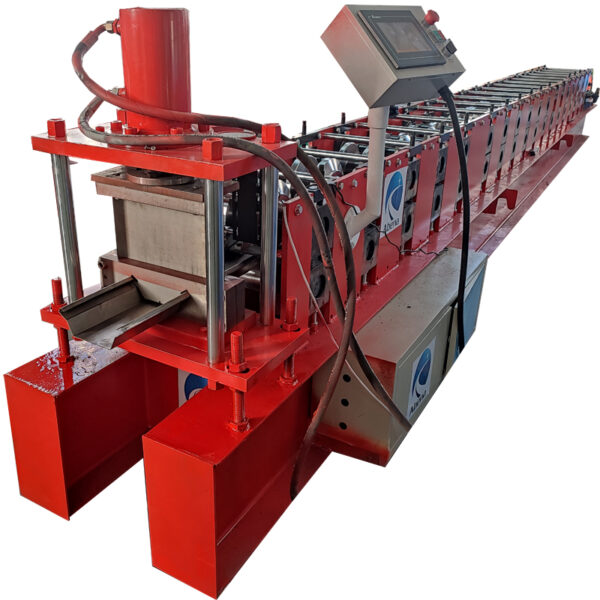

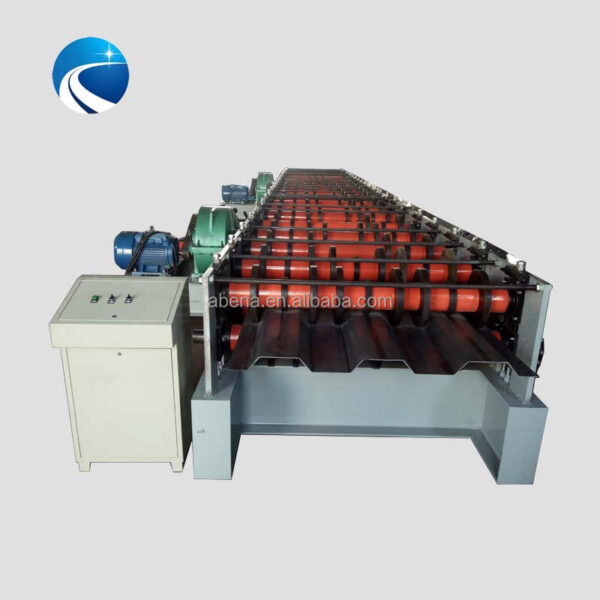

Forming Roller

1. Number of molding machine lanes: 10-18 rows 2. Roller material: 45# steel forged parts, hard chrome plating on the surface after finishing

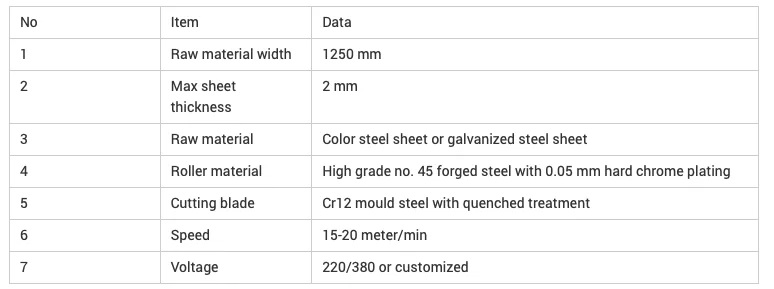

Product Specifications of Metal Coil Leveling Cutting Machine

Main Workflow Of Full Automatic Steel Coil Metal Sheet Cut To Length Line Machine:

Uncoiler —– Molding core —– Hydraulic System —– Automatic Control system —– Step Formed Mechanism —–Automatic Shearing Mechanism —– Products Receiving Tables

Main parameter of the roll forming machine

1 Raw material GI&PPGI&AL

2 width of the plate 1250mm

3. Thickness range 0.3-0.8mm

4.Roller stations :Three

5. Power 5.5kw

7. Cutter type Automatic hydraulic type

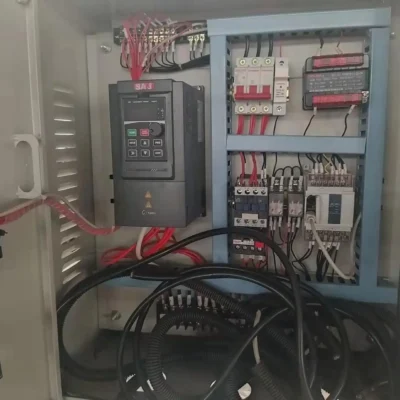

8. Control system Electric box with bottom to

control the length by yourself

9. Electric box PLC,frequency converter counter