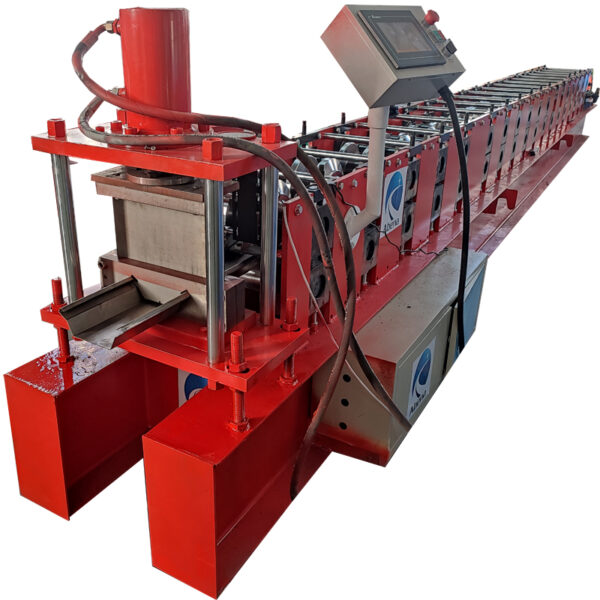

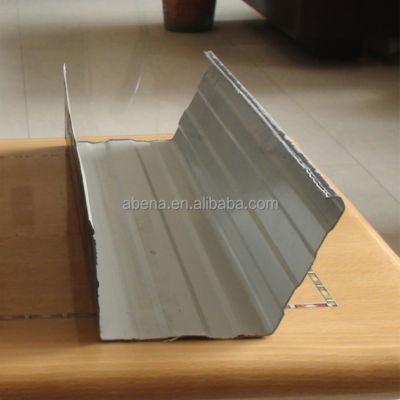

Gutter Making Machine Product Overview

The gutter machine can use color steel or aluminum plate to make the gutter plate. The forming plate is rolled, closed, and then bent and narrowed by special equipment. It has good weather resistance, simple design, simple installation, safe and durable, and noble. Elegant. The gutter board can be sprayed with rich colors according to the individual needs of users, and its metal texture and beautiful shape can bring a strong expressive force to the building.

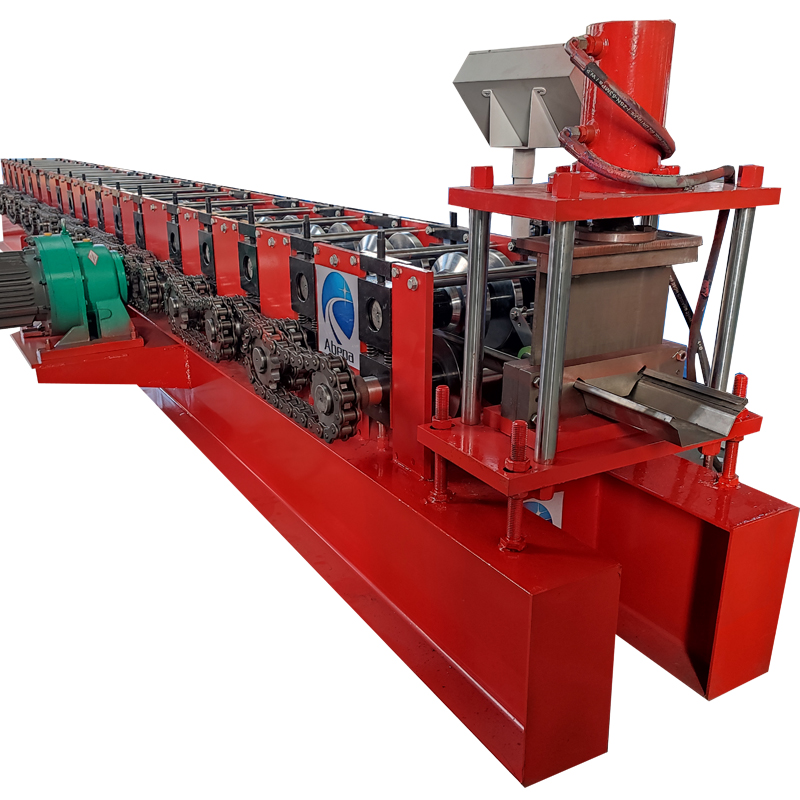

Details for Rain Gutter Making Machine

1. The whole machine is controlled by PLC, and multiple safety protections can be set to effectively avoid accidents;

2. The bed is made of steel plate welded parts and tempered to effectively eliminate internal stress and the body is not easy to deform;

3. The forming frame is welded by channel steel;

4. The roll shaft is made of 45# steel, which has been quenched and tempered;

5. The material of forming punching and shearing die is Gr12;

Hydraulic cut

Roll Forming Making Machine blade using more high precious machine making, The forming cutter of cold roll forming machine can cut raw materials of different materials.Our scissors can usually cut 0.3-0.6 mm steel plates.

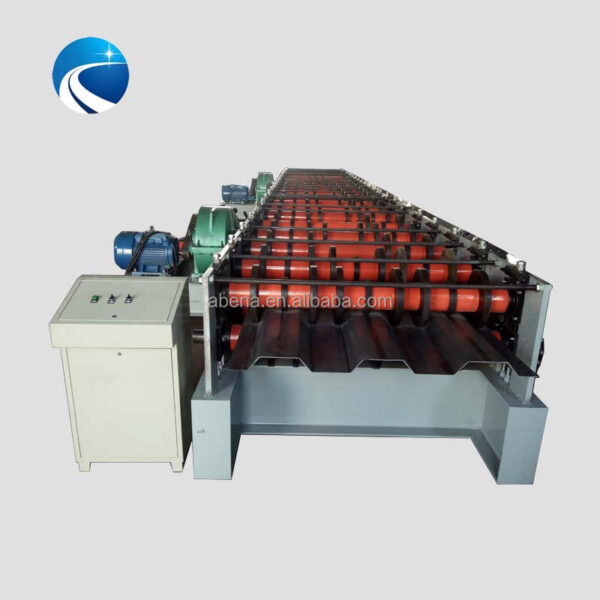

Main rollers

Roof sheet make machine forming roll quality will decide roof sheet shapes, we can according to your local roof shape customized different type rollers,Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

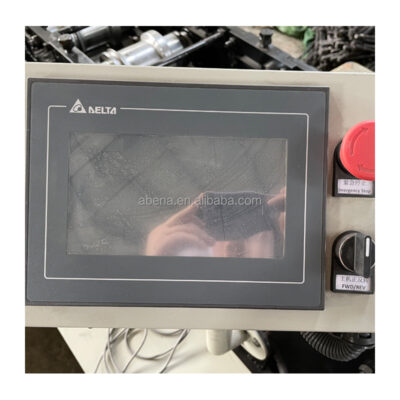

PLC control

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

Hydraulic station

Hydraulic station motor: 4 KW

Hydraulic oil:46# hydraulic oil

Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

Rain Gutter Making Machine of main parameter

|

Suitable to process

|

PPGI PI

|

|

Feeding width

|

as customer’s needs

|

|

Thickness of the plate

|

0.3-0.8mm

|

|

Roller stations

|

18 roller stations

|

|

Diameter of the roller

|

80mm

|

|

Rolling material

|

Carbon Steel 45#

|

|

Main motor power

|

5.5kw

|

|

Material of the cutting blade

|

Cr12 mov

|

|

Hydraulic cutting power

|

4kw

|

|

Processing precision

|

Within 1.00mm

|

|

Control system

|

Delta PLC control system

|

|

Side panel of machine

|

16mm

|

|

Main structure of the machine

|

350 H steel

|

|

Voltage

|

380V 50Hz 3phases(changeable as needs)

|

|

Weight

|

about 6.5 tons

|

|

Dimensions

|

8000*1200*1500mm

|

Metal Roofing Water Gutter Making Machine of product show

Abena machinery factory can manufacture fascia cover machine, gutter machine , downspout machine with high quality and reasonable price to you, you will emjoy one stop purchase from us.